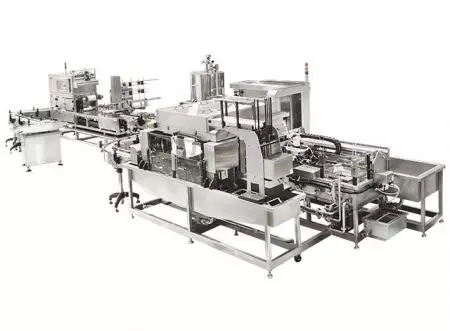

Continuous Tofu Pressing Machine

Continuous Tofu Pressing Machine

Continuous Tofu Pressing Machine

Automated, Consistent, and Designed for Modern Tofu Production

Tofu pressing is one of the most critical steps in tofu production. It defines texture, moisture, and yield. Yung Soon Lih's Continuous Tofu Pressing Machine automates this process, ensuring consistent firmness and high efficiency for both traditional and industrial tofu production lines.

Why Tofu Pressing Matters

Proper pressing determines tofu's final moisture content, texture, and shelf life. Manual pressing is inconsistent and labor-intensive. By contrast, continuous pressing systems improve quality control, reduce contamination, and significantly boost throughput, enabling manufacturing to meet modern production demands with conditions.

Features of YSL Continuous Tofu Pressing Machine

1.Automatic Pressure Control

Equipped with intelligent sensors, this system continuously monitors and adjusts pressure.

Continuous tofu pressing machine can give you:

-Ensures uniform tofu texture

-Minimizes product waste

-Continuous Conveyor Design

2.The built-in conveyor enables nonstop pressing and demolding, keeping production smooth and efficient.

Perfect for medium to large-scale tofu factories looking to expand capacity.

3.Hygienic and Easy-to-Clean

Constructed from SUS304 stainless steel, the machine supports CIP (Clean-in-Place) and fast drainage, guaranteeing high hygiene standards and minimal downtime between batches.

4.Adjustable Thickness & Speed

Easily control pressure and timing from the digital control panel.

Compatible with multiple tofu types:

regular, firm, pressed, and dried Tofu.

Continuous Tofu Pressing Machine's Technical Specifications

1.Customerize

According to the customer's taste of tofu, the operator can set parameters of pressure of time and intensity easier.

2.Convenience

Transporting and locating Tofu molds automatically.

3.Automatic

Continuous Tofu Pressing Machine operating automatically, after setting parameters.

Continuous Tofu Pressing Machine's Application Fields

1.Small/Mid-sized tofu factories

Ideal for tofu producers seeking to upgrade from manual pressing to semi- or fully-automated systems.

Ensures consistent texture, higher yield, and labor cost reduction. All within a compact footprint.

2.Vegan protein production lines

-Perfect for modern plant-based food manufacturers developing tofu as a protein-rich, sustainable ingredient.

-Supports continuous operation for stable, high-volume output that meets growing global demand for vegan foods.

3.Food processing plants (plant-based manufacturing)

-Easily integrated into existing production lines for soy-based, pea-based, or mixed plant protein products.

-Enhances production efficiency while maintaining strict hygiene and food safety standards.

4.Central kitchens / OEM food suppliers

-Designed for contract manufacturers or centralized kitchens that require high-capacity tofu production with reliable consistency.

-Simplifies workflow and ensures standardized tofu texture across every batch and delivery.

5.Educational and R&D Centers (Teaching and Innovation Applications)

-A valuable tool for universities, culinary schools, or food innovation labs studying tofu production technology.

-Enables experimentation with pressing parameters to explore texture, water content, and protein behavior under different conditions.

Benefits of Continuous Tofu Pressing System

| Benefit | Description |

|---|---|

| Consistency | Uniform tofu texture in every batch |

| Efficiency | Continuous operation, less downtime |

| Hygiene | Stainless steel design, easy cleaning |

| Labor Saving | Reduced manual handling |

| Scalability | Modular system for different capacities |

Engineer's Insight

Our team built this system to deliver stable, precise pressing for multiple tofu types.

The adjustable pressure design gives producers full control. Whether they're making soft, firm, extra firm tofu, or Tokan.

To improve safety and workflow, we integrated automatic stacking and mold transfer with sensor protection, reducing manual handling and ensuring smooth, reliable operation. The reinforced structure disperses force evenly, extending machine lifespan and cutting maintenance costs. With PLC + HMI control, each station presses 4-5 molds evenly, boosting consistency and efficiency. An optional auto-cleaning module supports fast sanitation, keeping production lines running with minimal downtime.

[How Continuous Tofu Pressing Machine work]

Contact Us for a Custom Solution

Every tofu product is different - firmness, texture, and water content vary by market.

YSL Food provides customized tofu pressing systems to fit your recipe, capacity, and space.

Hot articles

Forecast 2021-2026 tofu market and trends.

Affordable Startup Plan to Vegan Tofu Business

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

Continuous Tofu Pressing Machine | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.