What Is Okara? Understanding This By-Product from Soybean Wet Grinding and Separating Processes

What Is Okara? Understanding This By-Product from Soybean Wet Grinding and Separating Processes

Okara is not waste, but an inevitable by-product of soybean wet grinding and separation. The real challenge lies in inconsistent quality, moisture, and handling cost. Whether okara becomes a burden or a reusable resource depends largely on the stability and design of upstream grinding and separating processes.

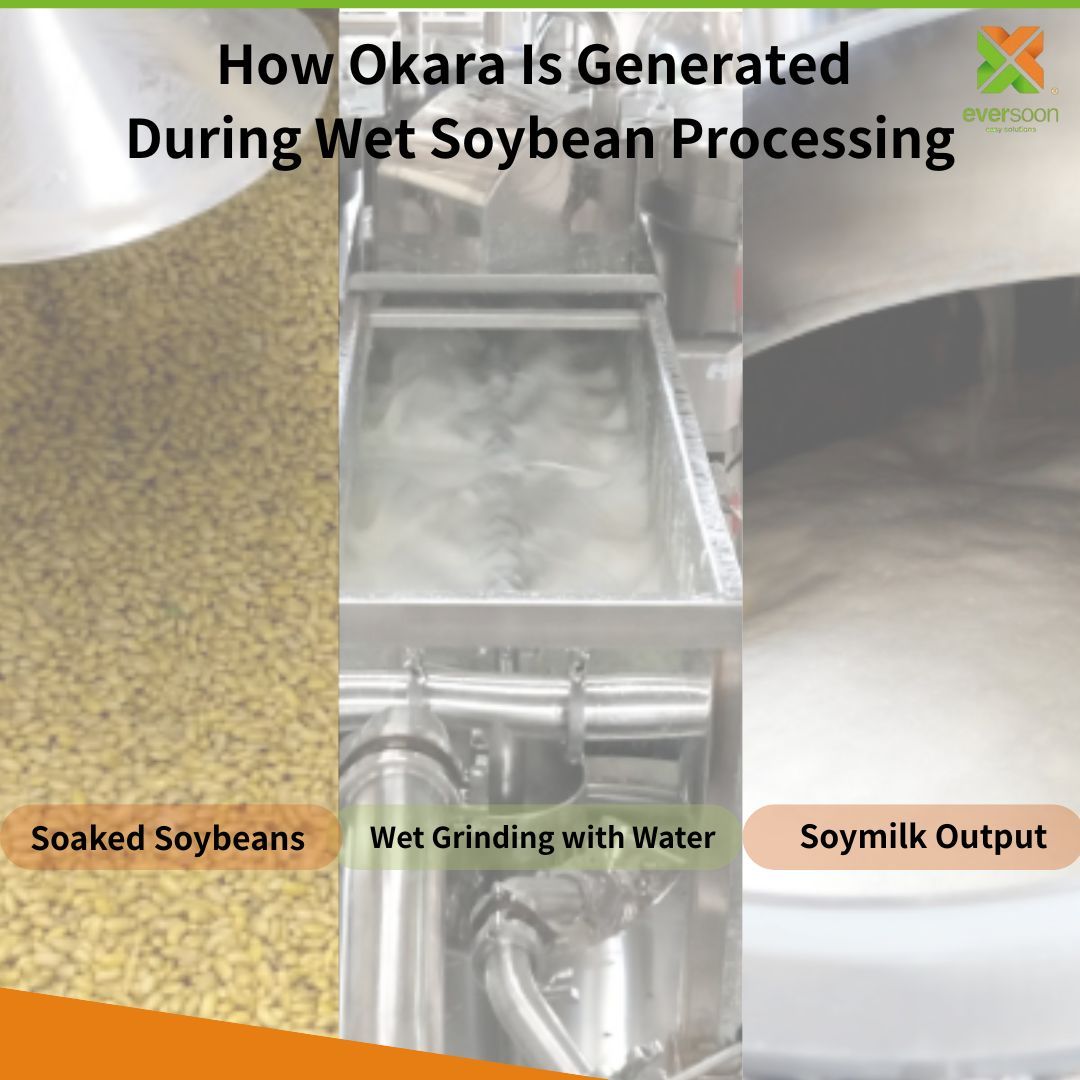

◆ What Is Okara and How Is It Generated in Soybean Processing?

Okara, or soy pulp, is the insoluble solid left after soybean wet grinding and liquid-solid separation. It is an inevitable outcome of wet processing, not an optional by-product. During production, soaked soybeans are ground to release proteins, oils, and soluble solids into the liquid, forming soy milk, while fibers and solids remain as okara. This residue does not appear in dry grinding, as liquid-solid separation is absent. Therefore, okara is inherently tied to wet processing and must be considered part of the overall process rather than a separate material to manage independently.

◆ Why Okara Is Difficult to Handle in Industrial Production

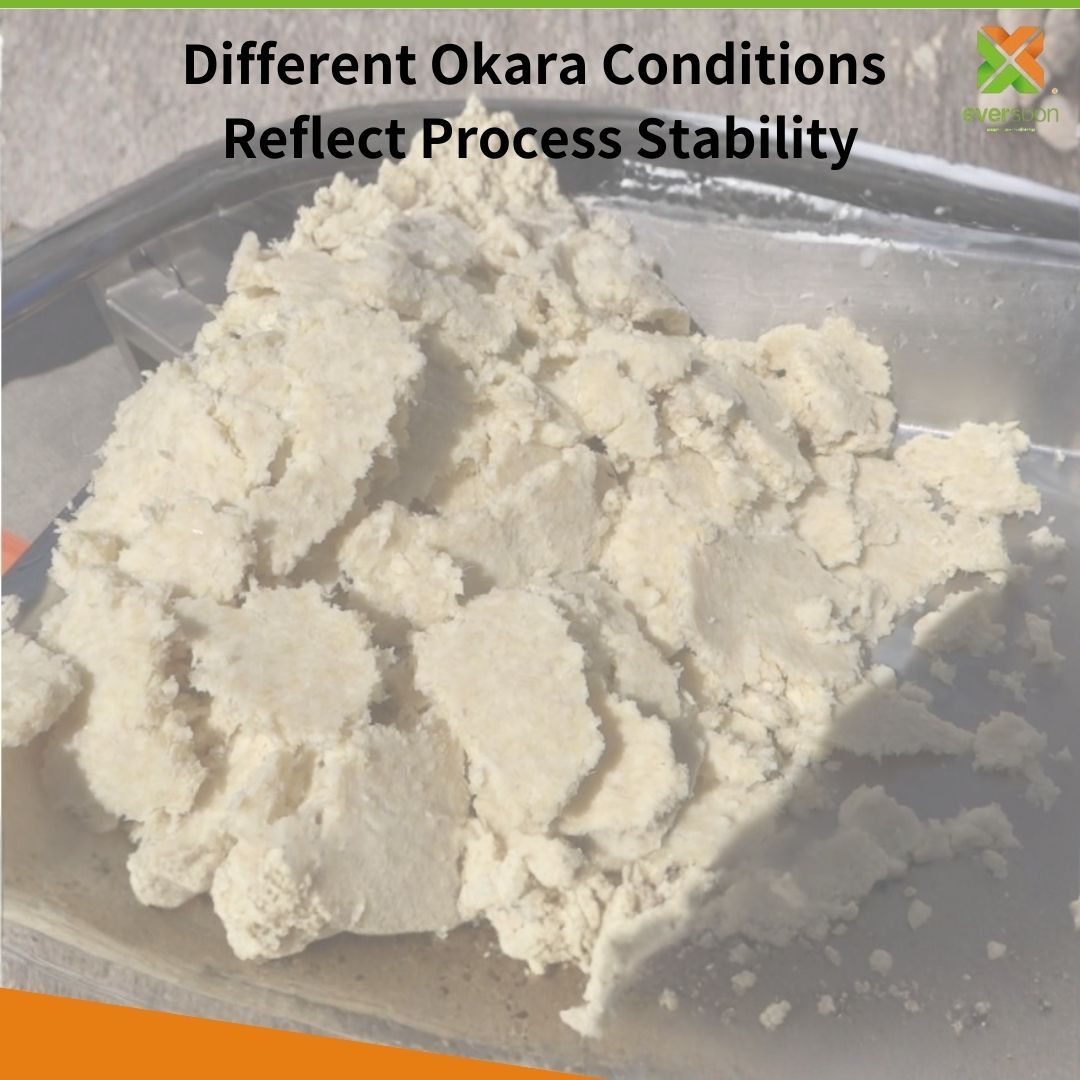

Okara presents multiple challenges for manufacturers. Its high moisture content (around 70-80%) makes it bulky, perishable, and costly to handle without proper separation or drying, while also promoting microbial growth and shortening shelf life. Its fiber-rich, insoluble solids give it low flowability, appearing as either fine sand-like particles or wet clumps depending on grinding, complicating mechanical conveying, dewatering, and drying. Most critically, inconsistent moisture levels and particle structure make downstream processes like fermentation, drying, or food applications unstable, limiting reliable reuse and causing the same process to succeed one day and fail the next.

◆ Key Insight: Okara Quality Is Determined Upstream, Not Downstream

Okara quality is determined upstream during grinding and separation. Grinding that is too coarse lowers soy milk extraction and increases moisture, while overly fine grinding damages fiber and raises separation difficulty. Separation systems must match grinding results, as upstream instability is amplified in continuous operation, causing visible quality drift in okara output. In other words, downstream equipment can only amplify the results of the upstream process; it cannot rectify fundamental flaws. These hidden costs are often underestimated.

Engineer’s Insight ——“Many customers believe okara is difficult to handle because the “downstream equipment isn’t powerful enough”. But in most cases, the root cause lies in the front-end process—uneven soaking, unstable grinding load, or particle size distribution that doesn’t match the separation design. Downstream systems only magnify upstream results; they can’t fix them.”

◆ Common Industrial Applications of Okara-and Their Limitations

Okara can be reused in various applications, but only when its quality is stable: Food applications require consistent moisture content and particle structure to ensure safety, texture, and formulation control. Drying and powder production are common routes but are highly energy-intensive and sensitive to moisture variation. Fermentation, animal feed, and other industrial uses depend on predictable physical properties for process stability. The key limitation is not technical feasibility, but process consistency; attempting to reuse unstable okara often results in higher costs than disposal.

◆ Common Misconceptions About Okara Processing Equipment

A common misconception is that certain machines can "eliminate" okara. From an engineering perspective, grinding and separating equipment perform physical separation, not chemical or biological decomposition. Their role is to separate soy milk from fiber, not destroy fiber structure. Confusing separation with decomposition leads manufacturers to invest in inappropriate equipment, expecting downstream systems to fix upstream process issues. This misunderstanding often results in misaligned expectations and poor investment decisions.

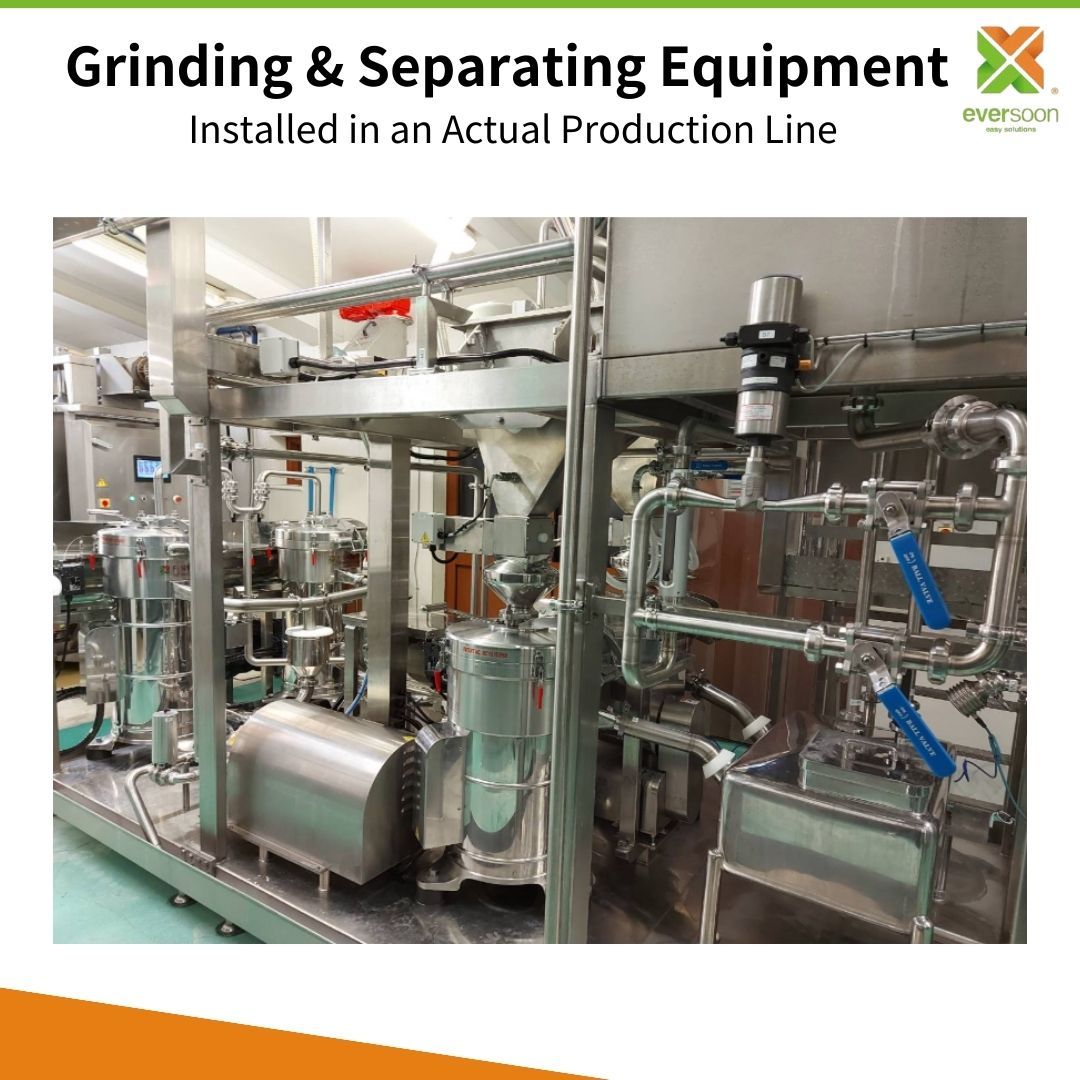

◆ Designing for Okara Value Starts with the Right Processing Equipment

At YSL Food, okara is treated as a process quality indicator rather than a waste stream. Stable okara output reflects stable grinding, effective separation, and well-controlled upstream conditions. The core design principles are stable wet grinding, continuous and properly matched separation, and industrial-grade operation capable of long-term consistency. When these conditions are achieved, okara quality stabilizes naturally, making reuse a practical option instead of an operational burden. This is why okara value begins with grinding and separation, not downstream disposal or reuse equipment.

[Find out more about: Soybean Rice Grinding & Separating Machine]

◆ Okara Is Not a Waste Problem, but a Process Design Issue

Okara reuse is not determined by downstream creativity, but by upstream discipline. Equipment design, process stability, and grinding-separating performance define okara's quality from the moment it is generated. For manufacturers, the takeaway is clear: if you want to manage okara effectively—or turn it into value—start with the grinding and separating process. Okara is not a problem to be removed, but a mirror reflecting the true condition of your production line.

[Explore Our Soybean Rice Grinding & Separating Machine] [Let's see how it works - Demo Video] [Want to know more? Contact us!]

Hot articles

Forecast 2021-2026 tofu market and trends.

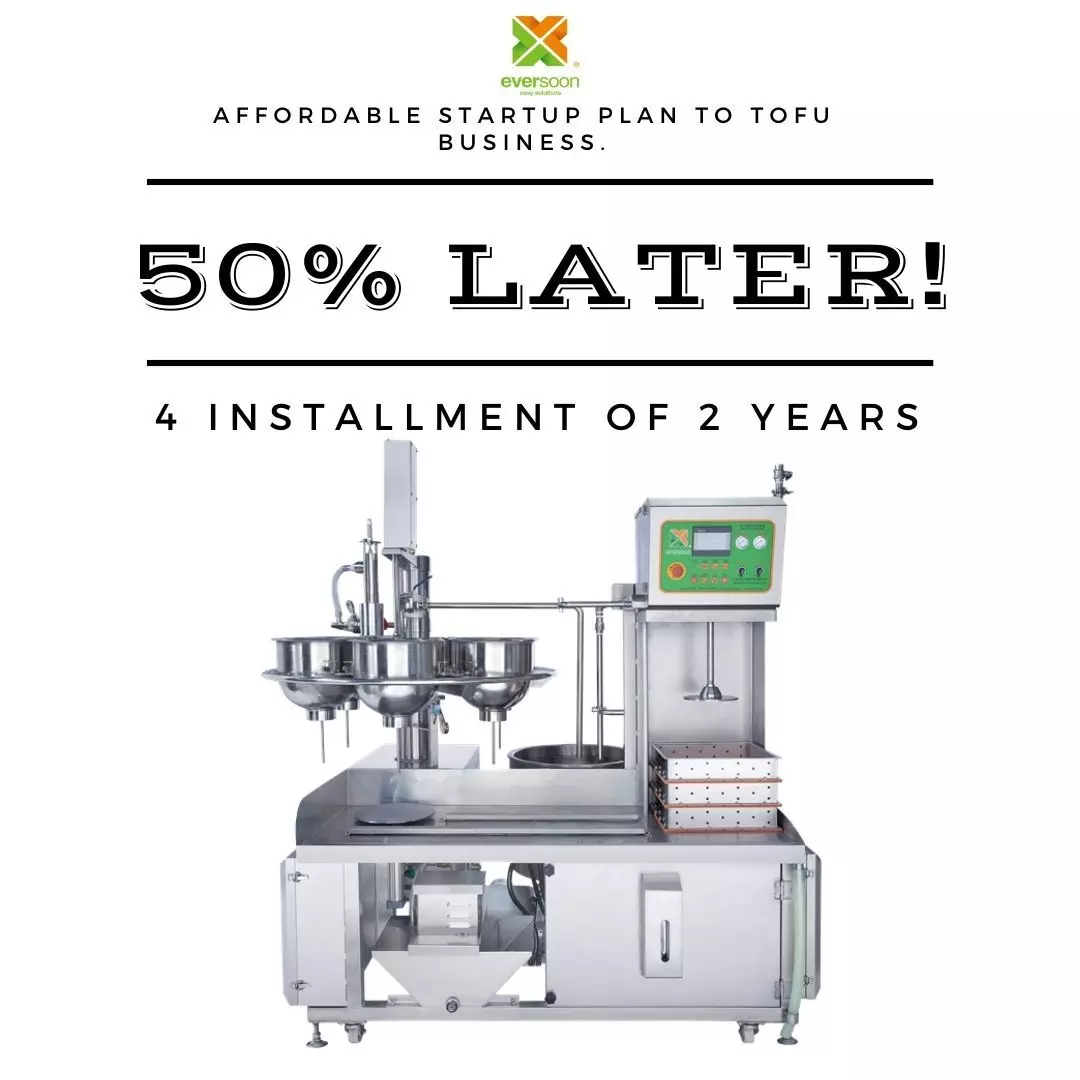

Affordable Startup Plan to Vegan Tofu Business

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

What Is Okara? Understanding This By-Product from Soybean Wet Grinding and Separating Processes | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.