Soy Milk Benefits: Why Soy Milk Is More Than a Health Trend

Continuous Type Automatic Soymilk Cooking Equipment Guide: From Nutrition to Commercial Production

Soymilk has evolved from traditional household beverage in to a globally consumed, plant-based drink with strict expectations for taste consistency, food safety, and supply stability. While consumers associate produce quality with raw materials, such as soybean origin or formulation, the reality of commercial production tells a different story. This guide examines soymilk cooking from an industrial perspective, shifting the discussion from manufacturing strategy, equipment selection, and long-term operational performance.

◆ Why Soymilk Requires Proper Cooking Equipment

In commercial production, cooking is not a simple heating task, it is a multi-functional process step that affects flavor, texture, safety, and shelf stability. Proper thermal treatment accomplishes several critical objective simultaneously:

1️⃣ Deactivation of off-flavor compounds

2️⃣ Protein denaturation and stabilization

3️⃣ Microbial control

4️⃣ Structural consistency

From a processing standpoint, cooking defines soymilk behaves as a controllable product of unstable ones. Many manufacturers can technically cook soymilk. The real challenge lies in doing it the same way, every hour, every day, and at scale.

| Batch-Style Cooking | Process-Controlled Cooking |

|---|---|

| Relies on visual judgment and operator experience | Controlled by fixed system parameters |

| Manual timing adjustments | Precise, repeatable residence time |

| Quality varies between batches | Consistent flavor and texture |

| Excessive foaming and additives required | Minimal foaming, no defoamers needed |

| Higher risk of customer complaints | Stable quality at commercial scale |

◆ Batch Type vs Continuous Type Soymilk Cooking Equipment

| Item | Batch-Type | Continuous-Type |

|---|---|---|

| Production | Batch process | Continuous flow |

| Quality | Inconsistent | Stable |

| Foaming | High, defoamers needed | Low, no defoamers |

| Labor | High | Low |

| Cleaning | Frequent stops | CIP, long runs |

| Scalability | Limited | Easy to scale |

Batch systems work for small-scale production. Continuous systems deliver stable quality, lower labor, clean-label production, and better long-term efficiency.

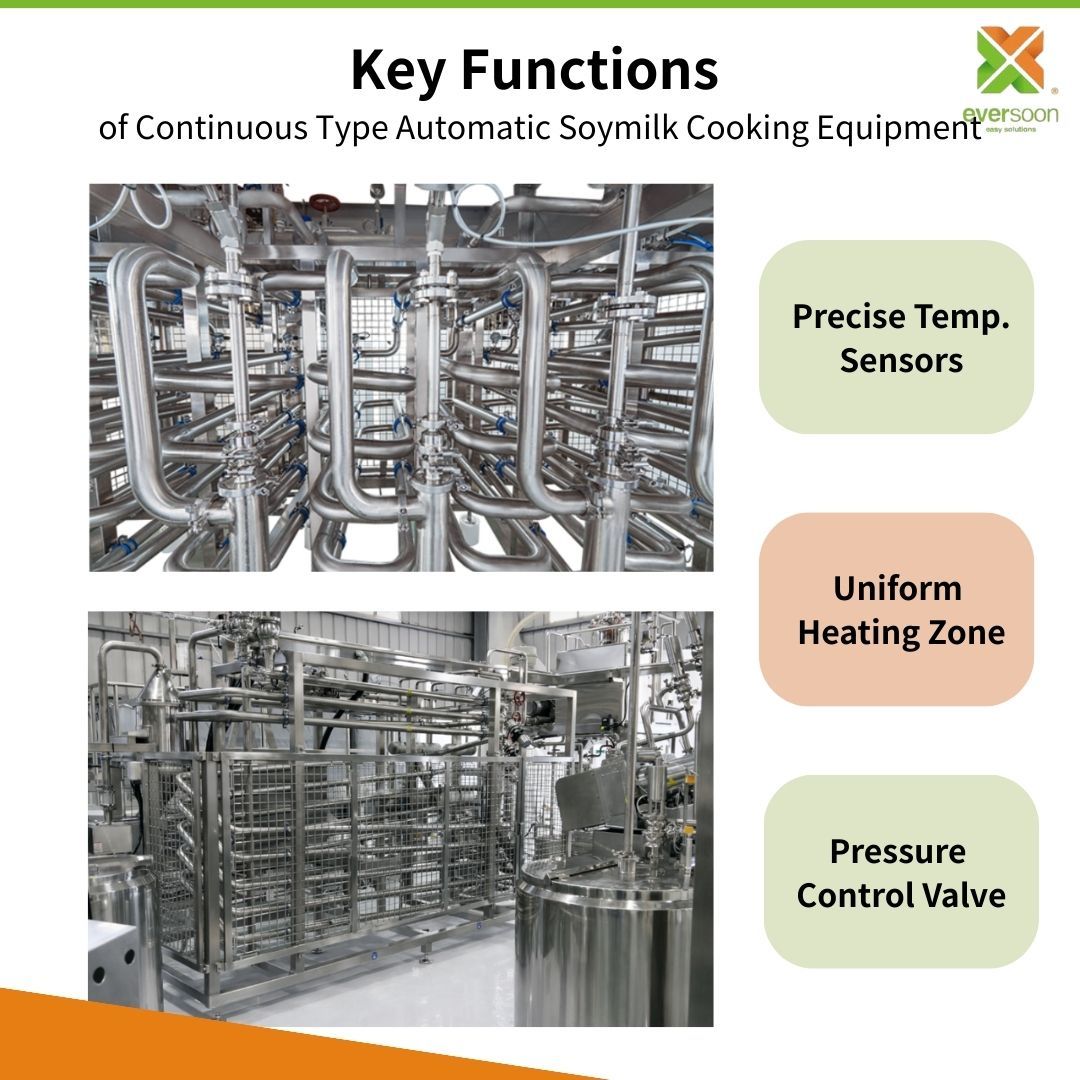

◆ Key Functions of YSL's Continuous Type Automatic Soymilk Cooking Equipment

1️⃣ Continuous Thermal Cooking with Precise Control The system applies controlled heat treatment under continuous flow conditions, ensuring consistent cooking temperature and residence time. This stabilizes protein structure, improves flavor, and reduces batch-to-batch variation common in traditional batch cooking.

2️⃣ Full-Pipe Cooking with Back-Pressure Design Soymilk is cooked under full-pipe conditions with controlled back pressure, significantly reducing foam formation. This design enables stable operation without the need for defoaming agents, supporting clean-label production requirements.

3️⃣ Stable Quality for Long Operating Hours Designed for extended continuous operation, the system maintains uniform cooking conditions over long production runs. This supports high-volume manufacturing while minimizing quality drift during prolonged operation.

4️⃣ Hygienic Pipeline and CIP-Compatible Structure Uniform pipe diameter and sanitary design allow effective CIP cleaning without disassembly. Dead corners are minimized to ensure food safety, reduce cleaning time, and support frequent production cycles.

5️⃣ Reduced Labor and Operator Dependency Automated temperature and flow control reduce reliance on manual monitoring. Operators shift from "watching the pot" to managing the production line, lowering labor intensity and improving operational efficiency.

◆ Why Continuous Cooking Systems Are Preferred in Large-Scale Soymilk Manufacturing

Solving Core Production Pain Points:

1. Stability: Uniform thermal exposure ensures consistent taste and texture

2. Labor reduction: Operators manage the line instead of "watching the pot"

3. Foam control: Minimal foaming eliminates the need for defoaming agents

4. Extended runtime: Systems can operate 20+ hours before CIP cycles

Impact on Brand and Supply Chain Reliability:

For OEM/ODM factories and growing brands, consistency is non-negotiable. Continuous cooking enables identical product profiles across large volumes, reliable delivery schedules, and lower risk of batch rejection.

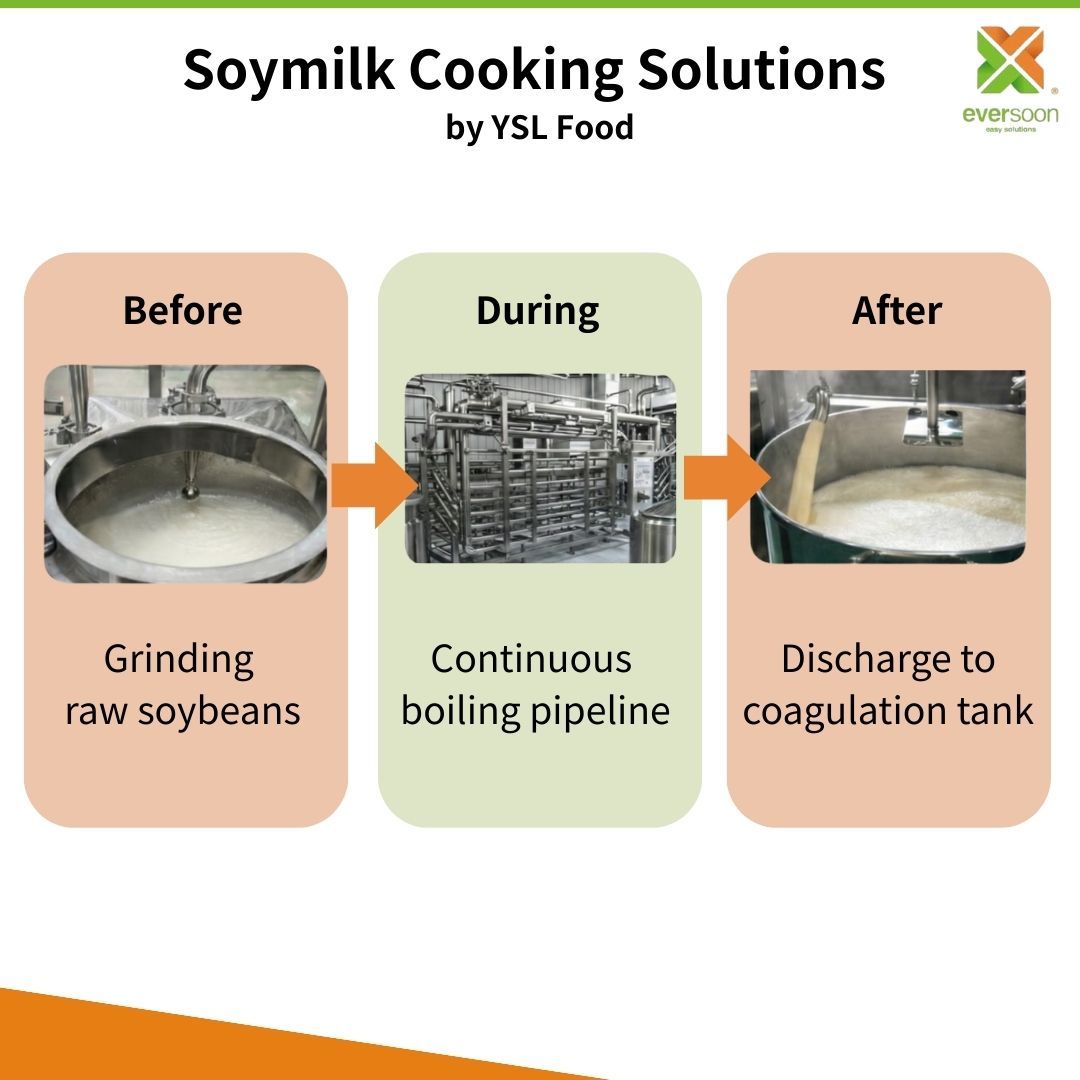

◆ Commercial Soymilk Cooking Solutions by YSL Food

YSL Food positions cooking equipment not as standalone machinery, but as part of an integrated processing solution.

Continuous Type Cooking System Applications:

1️⃣ Soymilk

2️⃣ Almond milk

3️⃣ Oat milk

4️⃣ Cashew milk

5. Other heat-treated plant-based beverages

Core Value for B2B Customers:

1️⃣ Process stability rather than recipe dependency

2️⃣ Scalable production architecture

3️⃣ Reduced operational complexity

◆ FAQ About Continuous Type Automatic Soymilk Cooking Equipment

Q1 | Why does soy milk quality tend to be inconsistent with traditional batch cooking? Batch cooking relies heavily on manual control of heating time, temperature, and agitation. Variations between batches often lead to differences in concentration, flavor, and mouthfeel.

Q2 | Why does excessive foaming occur, and is adding defoamers unavoidable? Unstable heating and uneven shear during batch cooking frequently generate excessive foam. A well-designed continuous cooking system maintains stable conditions, significantly reducing foam and eliminating the need for defoamers.

Q3 | How can buyers evaluate whether a system truly improves quality stability? Key indicators include precise temperature control, consistent residence time, and optimized pipeline design that prevents material buildup.

Q4 | Is it necessary to upgrade if batch cooking already produces acceptable output? Batch systems meet basic needs, but continuous systems are essential when longer operating hours, higher throughput, and consistent quality are required.

Q5 | What operational issues typically emerge after prolonged batch operation? Common issues include time-consuming cleaning, heavy night-shift labor, scaling or scorching, and gradual quality variation over time.

Q6 | What improvements do customers usually see after adopting a continuous cooking system? Customers typically report more consistent quality, fewer complaints, extended continuous operation (up to 20 hours), and clean-label production without defoamers.

◆ Choosing the Right Cooking Equipment Is a Production Strategy

Explore Our - Continuous Type Automatic Soymilk Cooking Equipment

Hot articles

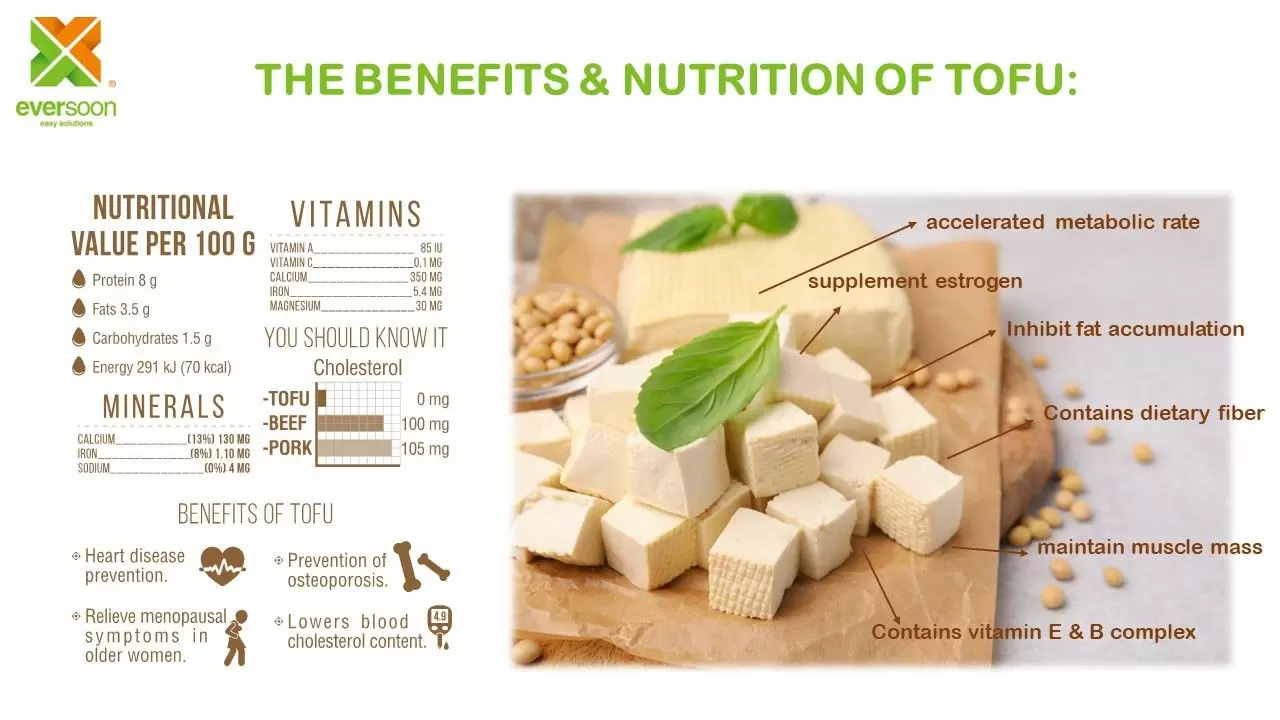

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

Benefits And Nutrition Of Tofu

Canada Food Guide Changes: More Veg, Less Meat, And No More Eating Alone

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

Soy Milk Benefits: Why Soy Milk Is More Than a Health Trend | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.