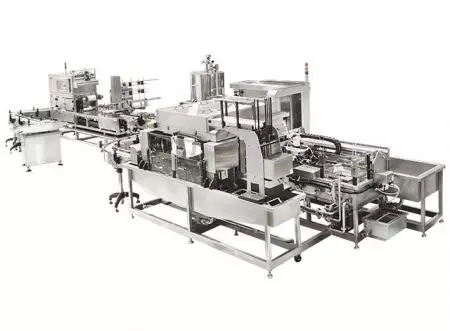

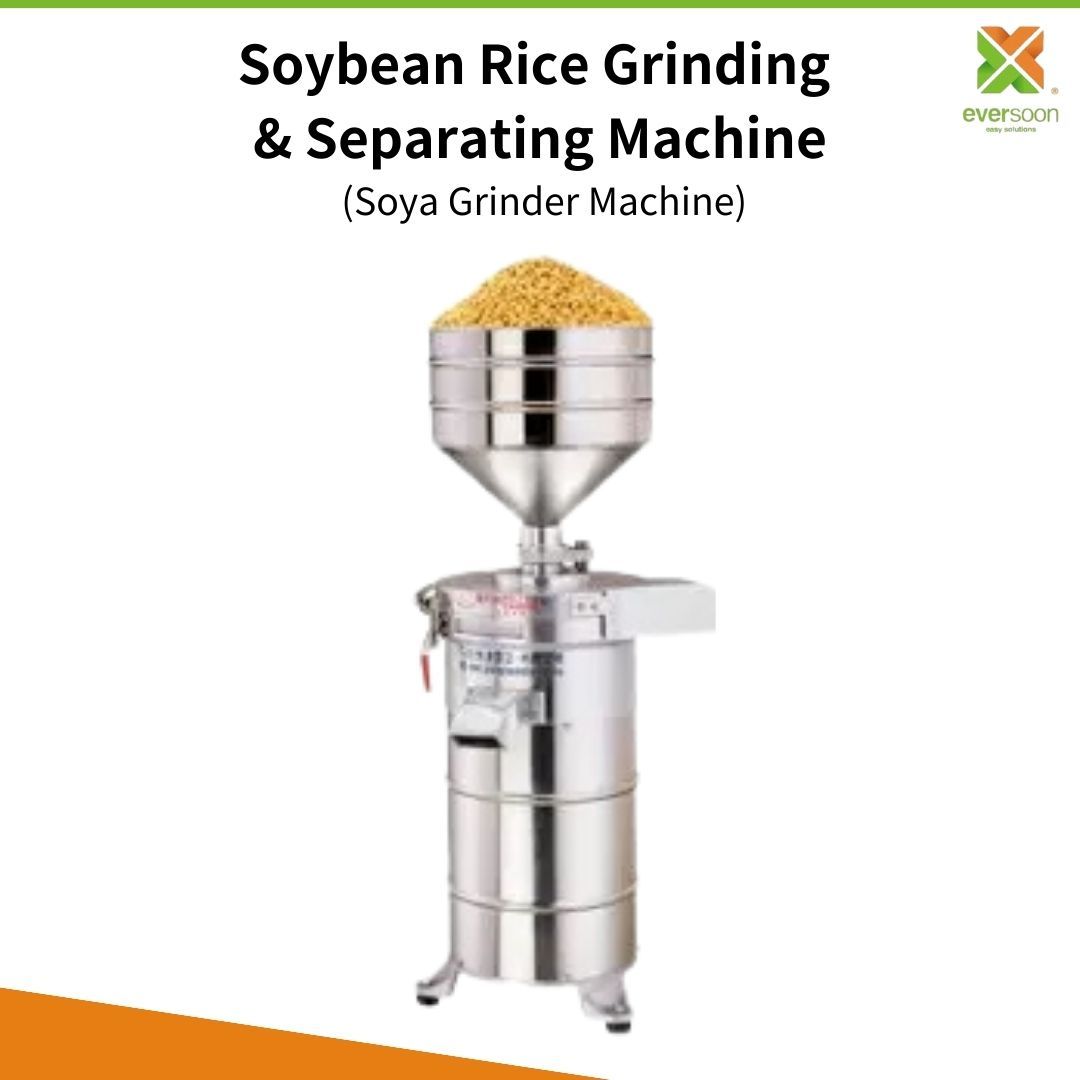

Soybean Rice Grinding & Separating Machine: How Grinding Technology Shapes Soy Milk and Tofu Production

Soybean Rice Grinding & Separating Machine: How Grinding Technology Shapes Soy Milk and Tofu Production

Grinding is the cornerstone of soy processing, determining protein extraction, pulp texture, and soy milk stability. Proper grinding ensures even particle size, efficient separation, and consistent tofu quality. Using general grinding equipment risks uneven extraction and unstable production, highlighting the need for specialized, food-grade soybean grinding technology.

◆ Grinding Machines in Soy Bean Processing: From General Principle to Food-Grade Application

Grinding machines work by applying shear, impact, or compression to break materials into smaller particles. Industrial or metal grinders are unsuitable for soy due to hygiene and precision concerns. Soybeans are high in moisture and protein, and require controlled grinding to preserve soluble nutrients and ensure smooth downstream separation.

| Feature | Impact on Product |

|---|---|

| Food-grade & hygienic design | Ensures soy milk and tofu safety |

| Wet-bean specific | Improves grinding efficiency and protein extraction |

| Grinding + separating integration | Reduces operation time, enhances consistency |

| Continuous & long-hour stability | Minimizes batch variation, ensures stable product quality |

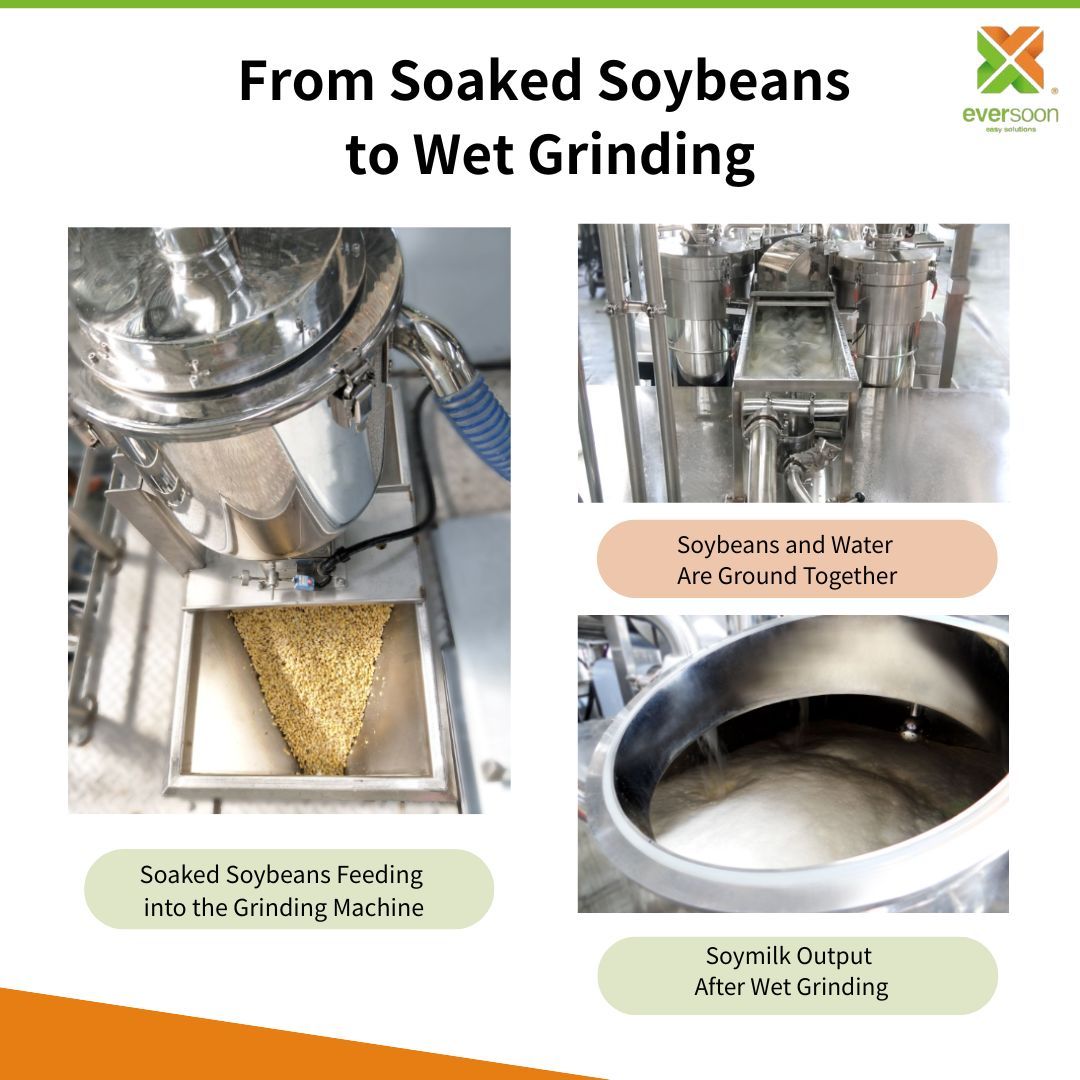

◆ From Soaking to Grinding: Why Moisture Control Defines Grinding Performance

Soaking sets the stage for effective grinding. Wet beans with 70-84% moisture allow optimal particle breakdown, protein release, and pulp uniformity. Traditional methods target 80-83%, while modern pressing allows 75-76%. Continuous, stable feeding ensures consistent grinding and prevents fluctuations in soy milk yield and texture.

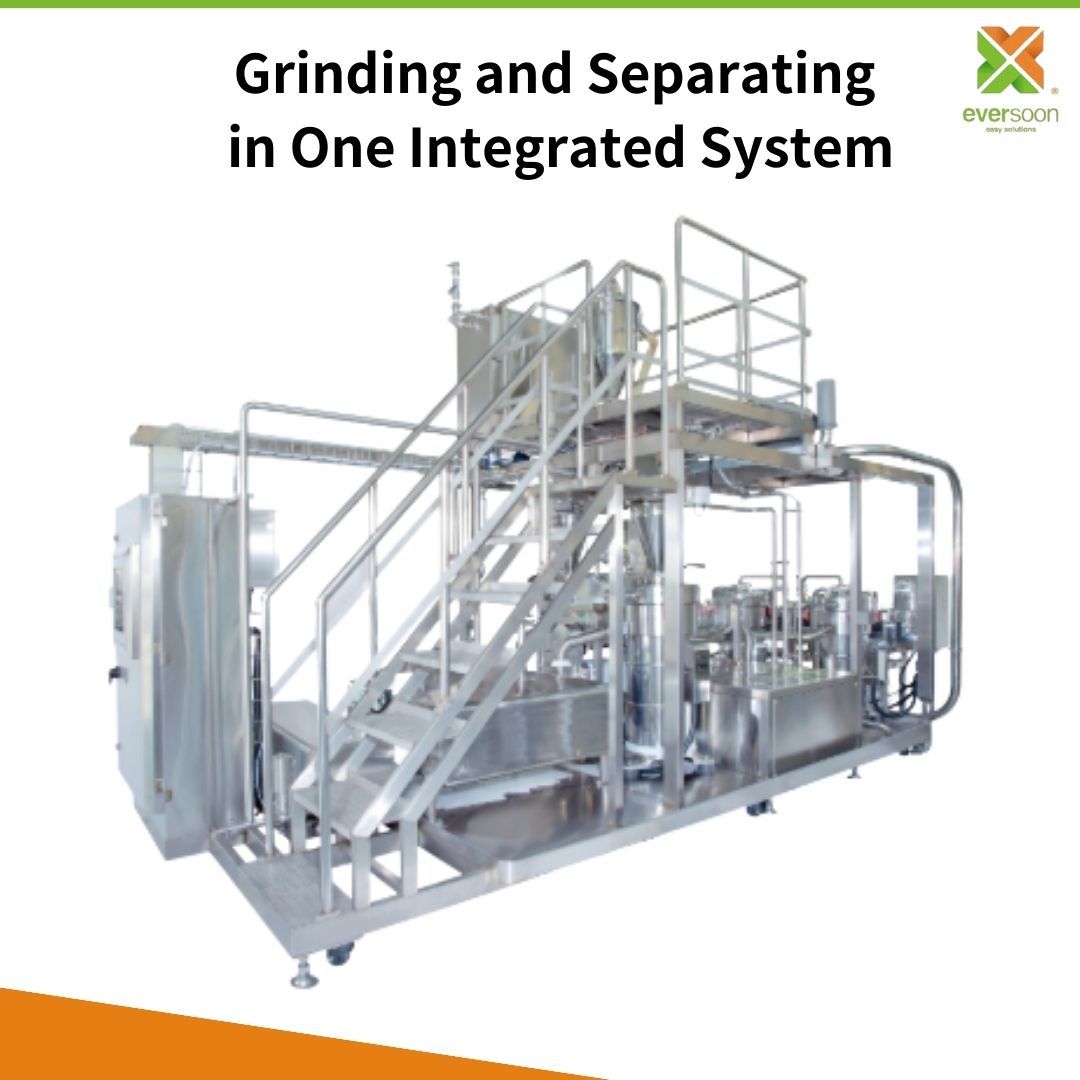

◆ Key Features of a Soybean Rice Grinding & Separating Machine for Industrial Production

Food-grade materials and hygienic design support safe production. Machines are tailored for wet, soaked soybeans, combining grinding and separating in one step. Continuous operation and long-hour stability maximize yield and maintain consistent soy milk and tofu quality, crucial for industrial-scale manufacturing.

◆ How Yung Soon Lih's Grinding Technology Supports Stable Soy Milk and Tofu Quality

Yung Soon Lih focuses exclusively on soy processing. Their F-16 Grinding & Separating Machine delivers high throughput and stable grinding, reducing batch variation and improving protein extraction. Consistent grinding ensures uniform tofu texture and predictable soy milk quality, critical for reliable industrial production.

Customer Feedback “After installing YSL’s F16 dual grinding system, extraction efficiency improved significantly. Grinding became stable, soy milk yield more predictable, and pulp consistency enhanced, making separation smoother. Overall, production efficiency and product quality increased noticeably.”

◆ Applications and Choosing the Right Grinding Machine for Your Factory

| Application | Description |

|---|---|

| Soy Milk | Optimizes protein extraction and smooth texture |

| Tofu | Provides consistent pulp for uniform tofu texture |

| Soy-based Products | For soy milk, tofu-derived products |

| Plant-based Protein | Serves as protein source for food production |

Grinding machines are essential for soy milk, tofu, soy-based foods, and plant-based protein products. Selecting the right equipment is a long-term investment, supporting production stability and product quality. Proper grinding reflects upstream process control, ensuring smooth downstream operations and consistent outcomes.

◆ Take the Next Step Toward Stable Soy Milk and Tofu Production

[Explore Our Soybean Rice Grinding & Separating Machine] [Let's see how it works - Demo Video] [Want to know more? Contact us!]

Hot articles

Forecast 2021-2026 tofu market and trends.

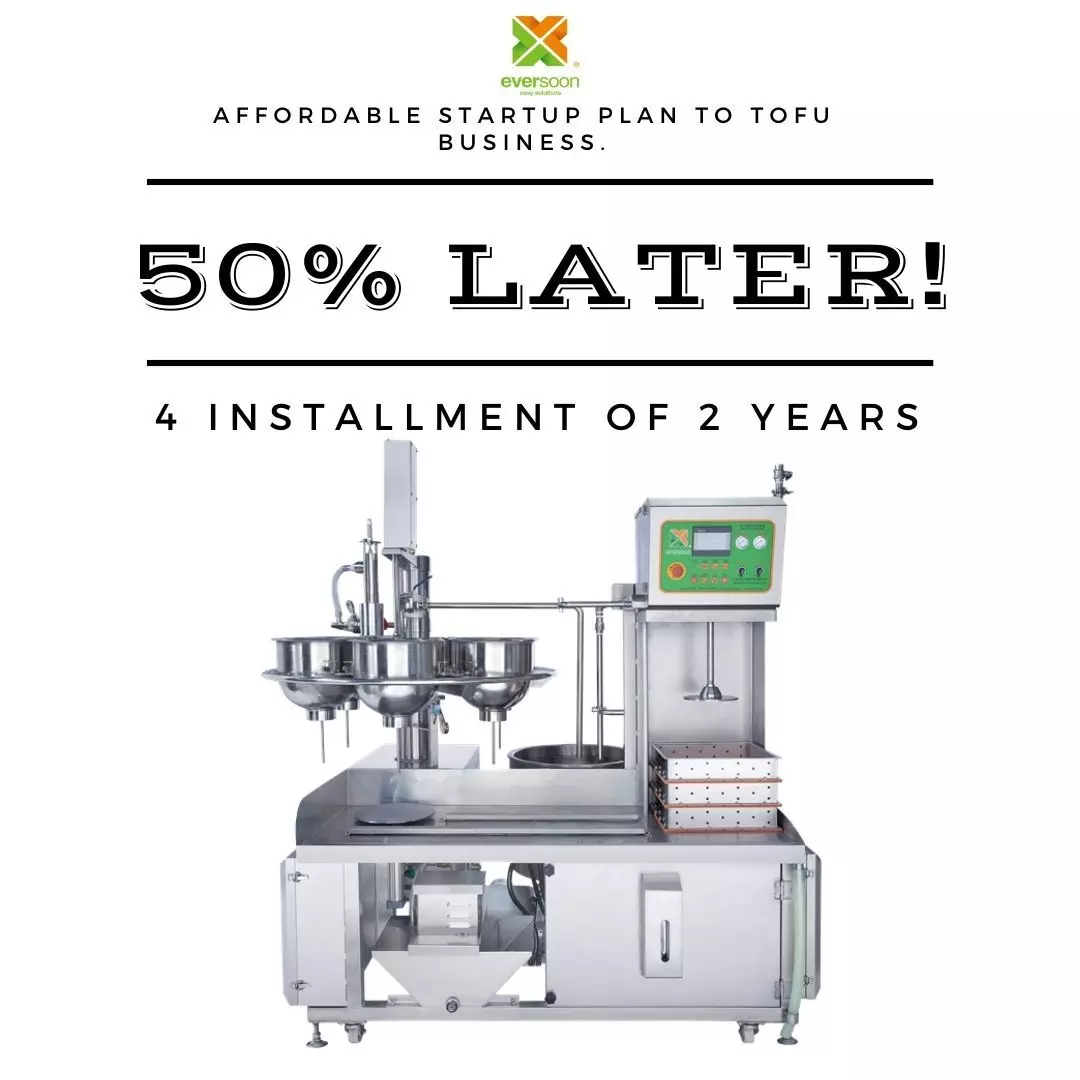

Affordable Startup Plan to Vegan Tofu Business

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

Soybean Rice Grinding & Separating Machine: How Grinding Technology Shapes Soy Milk and Tofu Production | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.