How to Make Tofu Step by Step — From Homemade to Professional Production

How to Make Tofu Step by Step — From Homemade to Professional Production

How to Make Tofu Step by Step - From Homemade to Professional Production

What You'll Need to Make Tofu

Key Ingredients

To start learning how to make tofu, you only need three essential ingredients: soybeans, water, and a coagulant.

- Soybeans

- Water

- Coagulant

- Industrial Use: Nigari, gypsum, and GDL are preferred in factory environments because they offer stable, predictable coagulation and consistent product quality. Nigari and gypsum yield firm, uniform blocks ideal for mass production, while GDL provides slow, controlled coagulation—perfect for silky tofu and automated processing lines.

- Home Use: Lemon juice and citric acid are common for home tofu-making thanks to their easy access and simple handling. Some home cooks also use small amounts of nigari for a more traditional texture. GDL is occasionally used at home as well, especially for making soft, pudding-like tofu with minimal effort.

Essential Tools

The essential tools needed are a Blender, Pot, Tofu Cloth, and a Tofu Mold or Box.

First, soak the soybeans until fully hydrated, then grind them with water to create a smooth slurry. Filter the mixture through a cloth bag to separate raw soy milk from okara.

Next, heat the soy milk to a boil, simmer briefly to remove raw flavors, then cool it to the proper temperature. Slowly add a coagulant, such as nigari, calcium sulfate, or GDL. After that, and gently stir until the soy milk forms a soft curd.

Once the curd sets, transfer it into a cloth-lined mold and press to remove excess water. Let it cool and firm up, then unmold and cut into blocks to produce finished tofu.

3. For Commercial Production

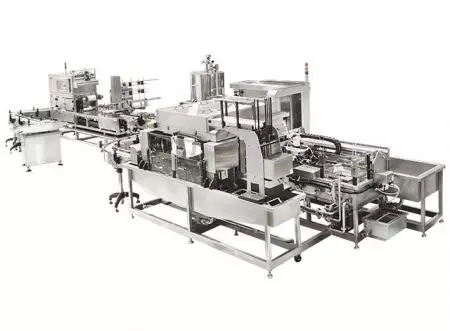

These basic tools are replaced by specialized equipment for precision and speed: Each machine plays a specific role in transforming soybeans into uniform, high-quality tofu blocks. All while minimizing manual labor and human error.

(1). Soy Milk Maker or Cooking Machine

This system automatically grinds, filters, and heats the soybeans, producing a continuous flow of fresh soy milk. Advanced temperature and mixing control ensure heating and prevent scorching, while integrated filtration systems remove okara efficiently to achieve a smooth, clean soy base.

(2). Coagulation Tank

Once the soy milk is prepared, it’s transferred to the coagulation tank, where precise temperature regulation and automated coagulation dosing guarantees state curd formation. These tanks are often equipped with agitators and digital sensors to maintain uniform texture across every batch. Whether producing silken, firm, or dried tofu.

(3). Tofu Pressing Machine

Finally, the curds are shaped in the tofu pressing machine, which applies even, programmable pressure to form consistent tofu blocks. The system controls pressing time, temperature, and pressure levels, resulting in uniform density and moisture content.

YSL Food’s advanced designs also include automatic de-molding and cooling functions, enabling a smooth transition to the packaging stage.

[ YSL’s recommendation: Meet Tofu Star]

Step-by-Step Guide: How to Make Tofu

| Step | Description |

|---|---|

| 1. Soak, Grind & Filter | First, soak the soybeans until fully hydrated, then grind them with water to create a smooth slurry. Filter the mixture through a cloth bag to separate raw soy milk from the leftover soy pulp (okara). |

| 2. Boil the Soy Milk | Heat the soy milk to approximately $95^{\circ}C$ to remove raw flavor, then cool it to the appropriate temperature for coagulation. |

| 3. Add Coagulant | Slowly add the coagulant (such as Nigari or Gypsum) and gently stir until the soy milk forms a soft curd. |

| 4. Press and Shape | Once the curd sets, transfer it into a cloth-lined mold and press to remove excess water. Let it cool and firm up, then unmold and cut into blocks. |

The Science Behind Coagulation

1. What Happens When Soy Milk Turns to Curd

When the coagulant meets hot soy milk, proteins unfold and bond together, trapping water and fat to form curds.

Temperature and pH must be just right — too cold and the tofu stays watery, too hot and it turns grainy.

In commercial tofu lines, sensors and digital controls keep these factors stable for smooth, consistent curds.

2. Choosing the Right Coagulant (Factory vs. Homemade)

(1). For factory

- Nigari (Magnesium Chloride)

Creates soft, silky tofu with a delicate flavor.

- Gypsum (Calcium Sulfate)

Produces firm tofu with added calcium, perfect for frying or grilling.

- GDL (Glucono-delta-lactone)

Produces smooth, custard-like tofu with a gentle, even coagulation.

(2). For homemade

- Citric Acid/Lemon Juice

Quick and easy for homemade tofu, but less precise for large batches.

Common Mistakes: Over-Stirring or Under-Heating

- Over-Stirring

Break curds and make tofu crumbly — stir gently, then let it rest.

- Under-Heating

Stops proteins from binding; soy milk should reach about 90–95°C before adding the coagulant.

YSL Food’s temperature-controlled systems help prevent these issues, keeping every batch of tofu perfectly set and uniform.

Homemade vs. Commercial Tofu Production

| Aspect | Homemade | Commercial (YSL Food Equipment) |

|---|---|---|

| Scale | Small batches for personal use | Medium to large-scale, continuous production |

| Consistency | Manual, variable | Automated and precise |

| Labor | Time-consuming and manual | Efficient, minimal labor required |

| Shelf Life | Best consumed fresh, short storage | Longer shelf life with proper packaging |

| Purpose | Ideal for personal enjoyment or experimentation | Designed for stable supply and business growth |

Common Questions About Making Tofu (FAQ)

- Why does my tofu break apart after pressing?

Usually, curds were undercooked or stirred too much. In industrial production, pressure and temperature are digitally controlled to avoid this.

- Which coagulant gives the softest texture?

Nigari produces the silkiest tofu, while gypsum gives a denser texture ideal for frying or grilling.

- How long should I press tofu for?

Pressing time is not fixed and depends on local conditions such as climate, soybean variety, and desired tofu firmness. Commercial tofu pressing machines allow operators to fine-tune pressure and duration, ensuring consistent results without relying on a universal time setting.

- Can I reuse the leftover soy pulp (okara)?

Yes! Okara is rich in fiber and protein, commonly used in bakery, snacks, or vegan meat alternatives.

- How do factories automate tofu-making?

With integrated soaking, grinding, coagulation, and pressing systems controlled by PLC (Programmable Logic Controller) panels. For small businesses, compact tofu machines offer an easy transition from handmade to automated production.

See How Professionals Make Tofu

From soaking to pressing, the process remains the same - but automation changes everything. Watch how YSL Food's tofu line turns simple soybeans into perfectly formed tofu blocks with zero manual handling.

Hot articles

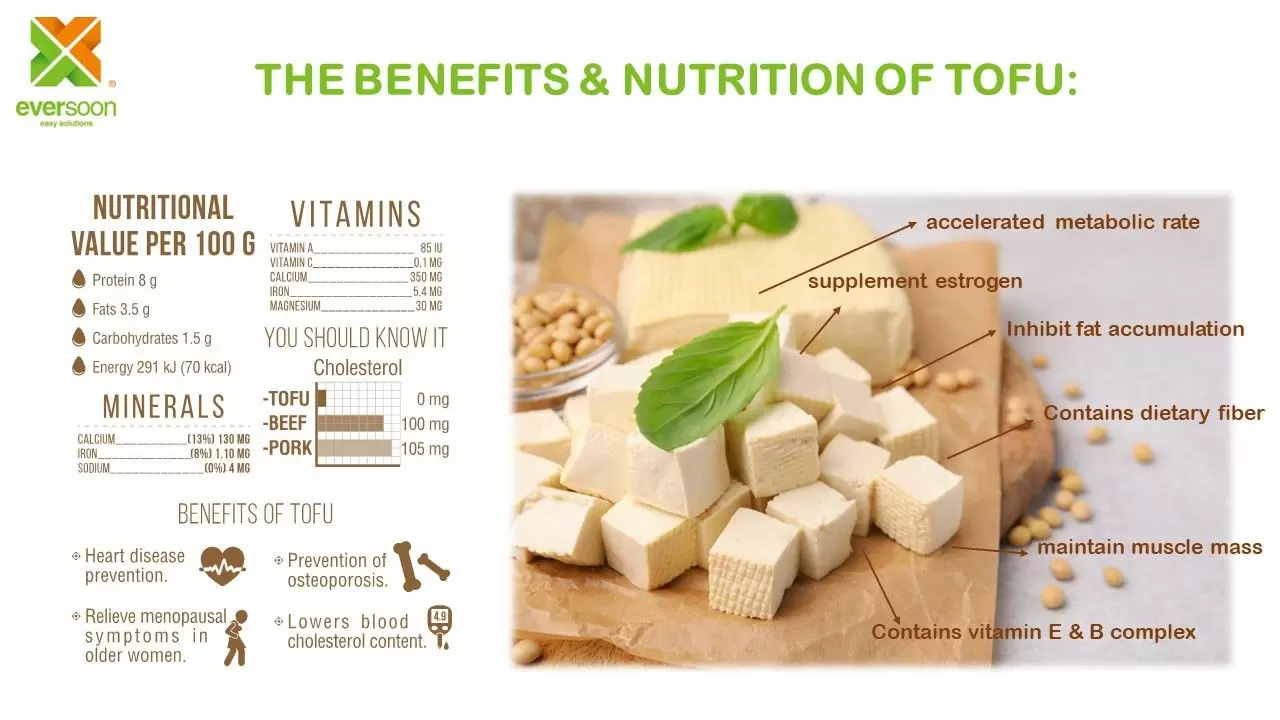

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

Benefits And Nutrition Of Tofu

Canada Food Guide Changes: More Veg, Less Meat, And No More Eating Alone

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

How to Make Tofu Step by Step — From Homemade to Professional Production | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.