-

English

- English

- Español

- Português

- Français

- Italiano

- Deutsch

- Русский

- Suomen

- Svenska

- Dansk

- česky

- Polska

- Nederlands

- Türkçe

- العربية

- हिन्दी

- Indonesia

- ไทย

- Bahasa Melayu

- Việt

- Български

- Javanese

- slovenčina

- slovenščina

- తెలుగు

- Filipino

- Română

- فارسی

- বাঙ্গালী

- українська

- Magyar

- עברית

- Norsk

- Eesti

- Hrvatska

- Gaeilge

- 中文 (繁體)

- 中文 (简体)

- 日本語

- 한국어

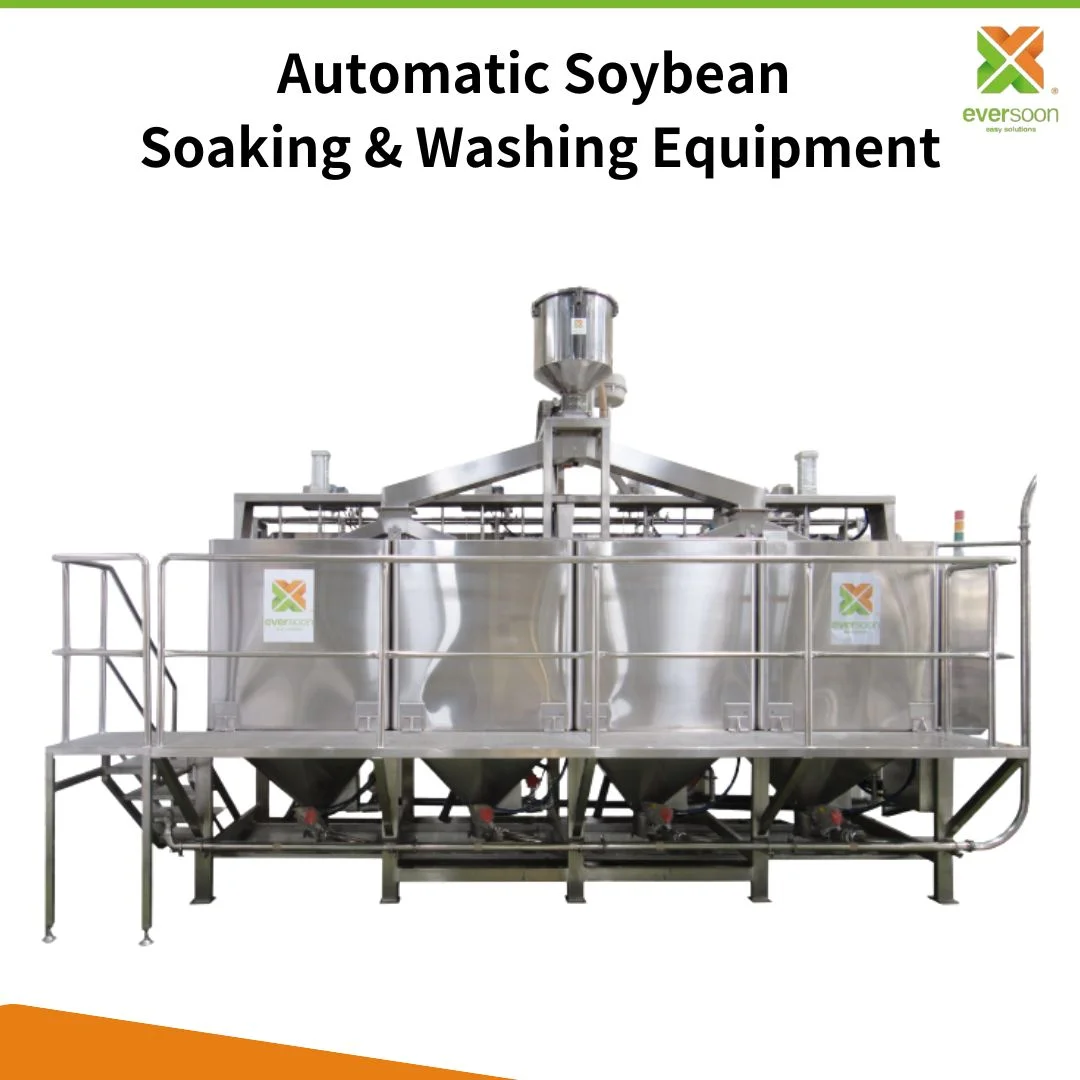

Automatic Soybean Soaking & Washing Equipment: Boost Tofu & Soy Milk Yields

Automatic Soybean Soaking & Washing Equipment: Boost Tofu & Soy Milk Yields

The First Step to Better Tofu and Soy Milk Production.

◆ Why Soybean Preparation Matters in Tofu Production

1️⃣ The Foundation of High-Quality Tofu and Soy Milk

Soybean pre-processing directly shapes flavor, texture, extraction efficiency, color, and product stability.

Properly cleaned and hydrated soybeans lead to smoother soy milk, richer protein release, and fewer defects during coagulation.

Poorly cleaned or unevenly soaked soybeans, by contrast, can cause beany flavor, gritty texture, inconsistent firmness, and unstable yields.

2️⃣Common Problems in Manual Soaking & Washing

Manual handling is often unpredictable. Impurities such as dust, sand, and broken soybeans slip through simple hand-washing.

Soaking is uneven because settled soybeans at the bottom receive less water circulation.

Temperature varies from batch to batch, and the hygiene risk rises when workers must handle large volumes of wet soybeans.

The process also requires significant labor and nighttime operations.

3️⃣ Why Modern Factories Need Automated Systems

As food safety standards rise globally, factories need standardized, traceable, and labor-efficient operations.

Automated Soybean soaking and washing ensures consistent quality, improves hygiene, reduces dependency on skilled labor, and aligns with HACCP, CE, and international compliance requirements.

◆ How Industrial Soybean Washing Machines Transform Production Lines

1️⃣ Overview of the Equipment's Purpose

This equipment is engineered to wash soybean, remove impurities, ensure uniform hydration, and improve downstream grinding, cooking, and coagulation performance.It replaces unstable manual processes with controlled, automated precision.

2️⃣ How It Fits Into a Tofu Production Line

| Stage | Purpose | Link to Soybean Prep |

|---|---|---|

| Soaking & Washing | Clean + hydrate soybeans | Decides flavor & extraction stability |

| Grinding | Release protein | Hydration affects grind efficiency |

| Cooking | Heat & sterilize | Clean soybeans reduce off-flavors |

| Coagulation | Form curds | Consistent soy milk consistent curds |

| Pressing | Shape texture | Moisture uniformity starts at soaking |

| Molding | Final tofu form | Appearance depends on earlier steps |

These rising product lines underscore the strategic need for automated tofu and soy milk technologies in modern production environments.

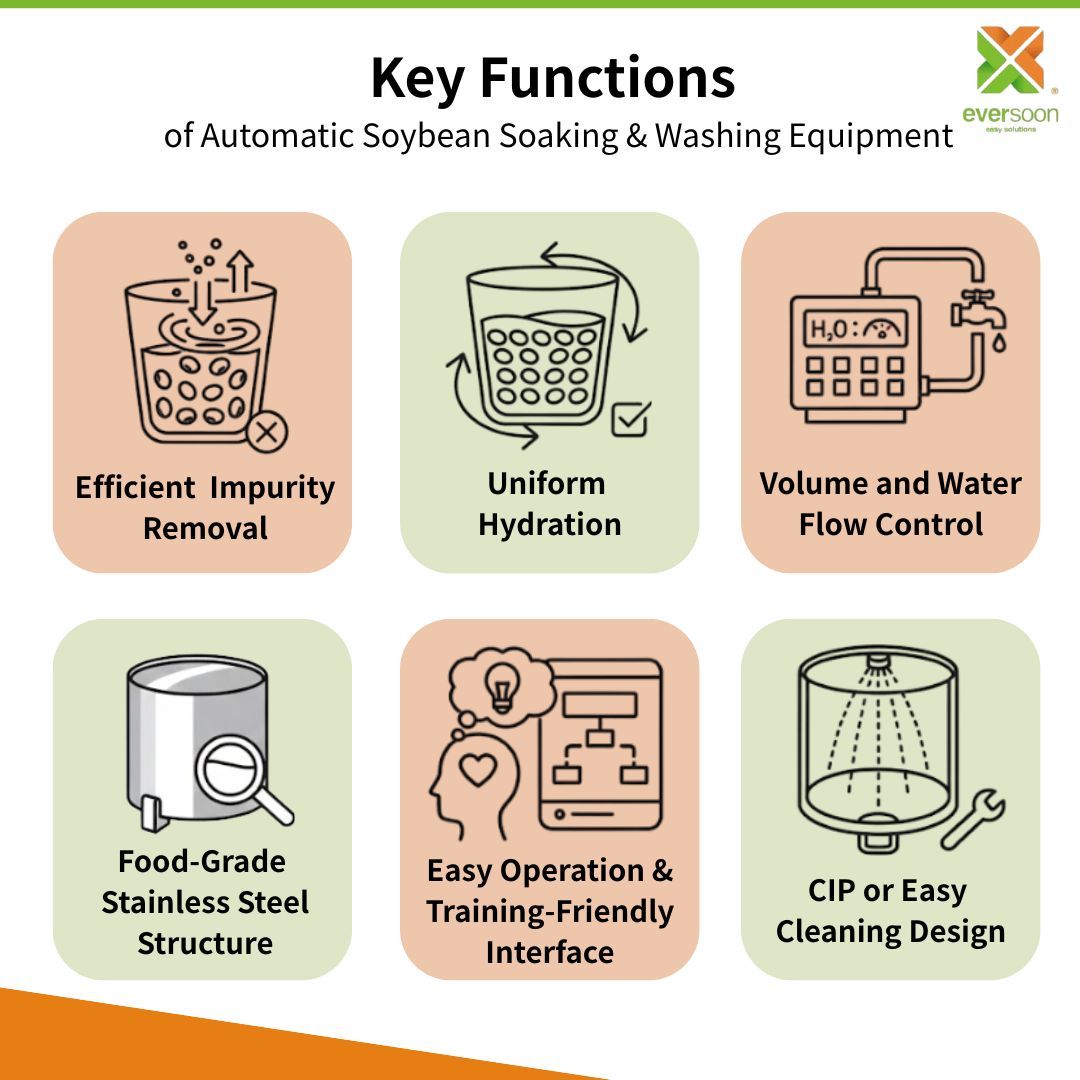

◆ Key Functions of YSL's Automatic Soybean Soaking & Washing Equipment

1️⃣ Efficient Impurity Removal

Strong water agitation and overflow discharge separate sand, debris, floating soybeans, damaged soybeans, and fine particles.

This prevents contaminants from entering the grinder and reduces microbial risks.

2️⃣ Uniform Hydration

Water circulation and aerated bottom agitation allow every soybean to absorb moisture evenly.

This minimizes batch-to-batch differences and improves extraction stability.

3️⃣ Volume and Water Flow Control

Automated sensors monitor water level and refill conditions.

The system controls soaking time, water volume, and flow rate to standardize soybean preparation across seasons and temperature changes.

4️⃣ Food-Grade Stainless Steel Structure

Built with SUS304 stainless steel and sanitary welding, the tank minimizes dead corners and simplifies cleaning and inspection.

All pipelines and surfaces meet food-grade requirements.

5️⃣ Easy Operation & Training-Friendly Interface

The HMI panel (Human-Machine Interface) provides intuitive buttons and programmable settings. Operators can quickly master the workflow, reducing training costs.

6️⃣ CIP or Easy Cleaning Design

Quick water replacement, efficient drainage, and easy-access pipelines support hygienic cleaning routines.

Factories can maintain stable sanitation even during high-volume production.

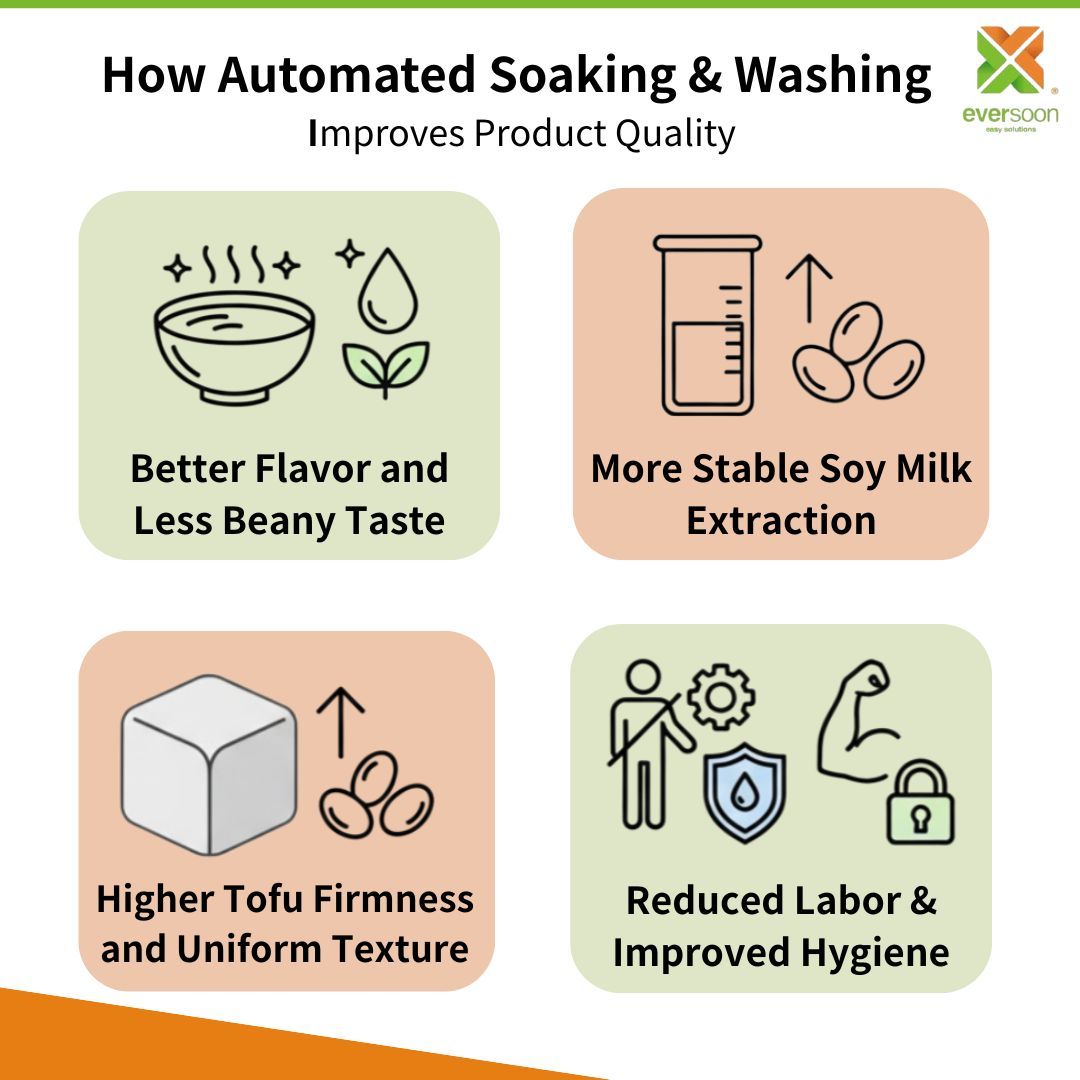

◆ How Automated Soaking & Washing Improves Product Quality

1️⃣ Better Flavor and Less Beany Taste

By removing dust, microbes, and degraded Soybean particles, the equipment reduce off flavors and enhance the natural sweetness of soy milk.

2️⃣ More Stable Soy Milk Extraction

Uniformly soaking soybean grind more consistently, producing stable protein concentration and smother milk texture.

3️⃣ Higher Tofu Firmness and Uniform Texture

Consistently hydration produces predictable coagulation behavior, resulting in firmer, more uniform tofu.

4️⃣ Reduced Labor & Improved Hygiene

Less manual handling means lower contamination risk and safer production environments—especially valuable for regulated markets.

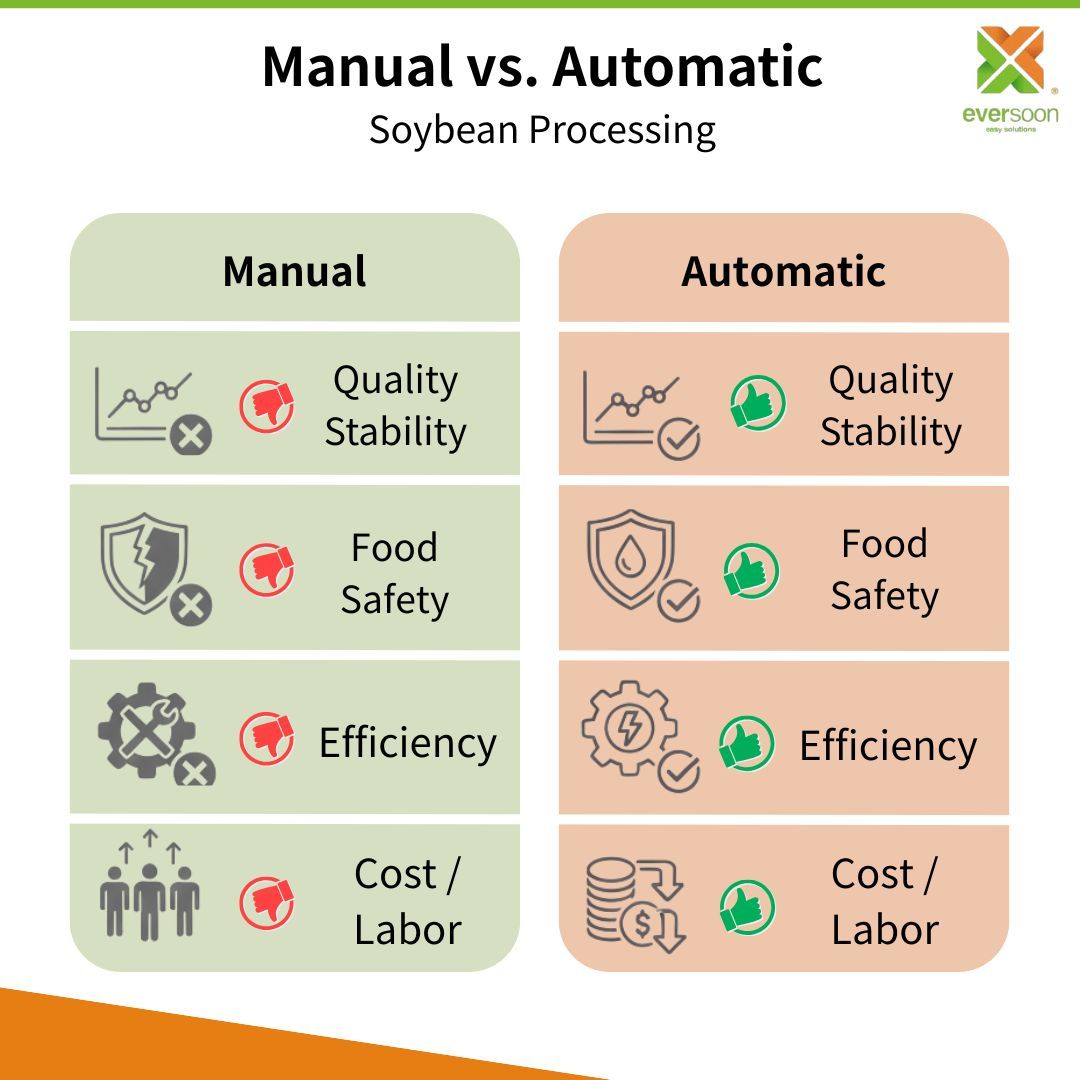

◆ Comparing Manual vs. Automatic Soybean Processing

| Category | Manual | Automatic |

|---|---|---|

| Quality Stability | (1). Soaking uneven (2). impurities often stay. | Clean, uniformly hydrated soybeans every batch. |

| Food Safety | Higher contamination risk. | Controlled washing + fewer human touchpoints. |

| Efficiency | (1). Need night-shift labor (2). Heavy handling. | (1). No night work (2). fully scheduled. |

| Cost / Labor | Daytime and night-shift labor | Labor 50-70% |

◆ Application Scenarios: Who Benefits from This Equipment?

1️⃣ Mid-Large Scale Tofu Factories

Greater capacity and more stability to finished tofu firmness.

2️⃣ Soy Milk Manufacturers

Higher extraction yields, smoother milk, and improved shelf-life.

3️⃣ Plant-Based Protein Producers

ideal for pea-soy blends, hybrid protein beverages, and other plant-based formulations where Soybean quality affects downstream mixing and texture.

4️⃣ Central Kitchens / OEM / Meal Prep Brands

Reliable supply, stable batch-to-batch consistency, and simplified standardization for large-scale menu production.

◆ Why Choose YSL Food Machine?

1️⃣30+ Years in Tofu & Soy Milk Production Technology

Deep industry roots and trusted expertise.

2️⃣ CE-Certified Food-Grade Systems

All equipment meets global safety and hygiene standards.

3️⃣ Integrated Production Line Expertise

YSL supports full-line planning-not just single machines-ensuring seamless compatibility from soybean intake to final tofu products.

4️⃣Global Clients & Local Support

Used in Europe, Canada, the United States, Southeast Asia, and regions with large temperature variations.

Well-suited for global tofu producers needing robust and stable soybean preparation.

◆ Ready to Improve Your Soybean Processing Workflow?

Take the next step toward a more efficient, scalable, and reliable production line. YSL offers the expertise and equipment to support your growth.

➡️Explore Our Automatic Soybean Soaking & Washing Machine

Hot articles

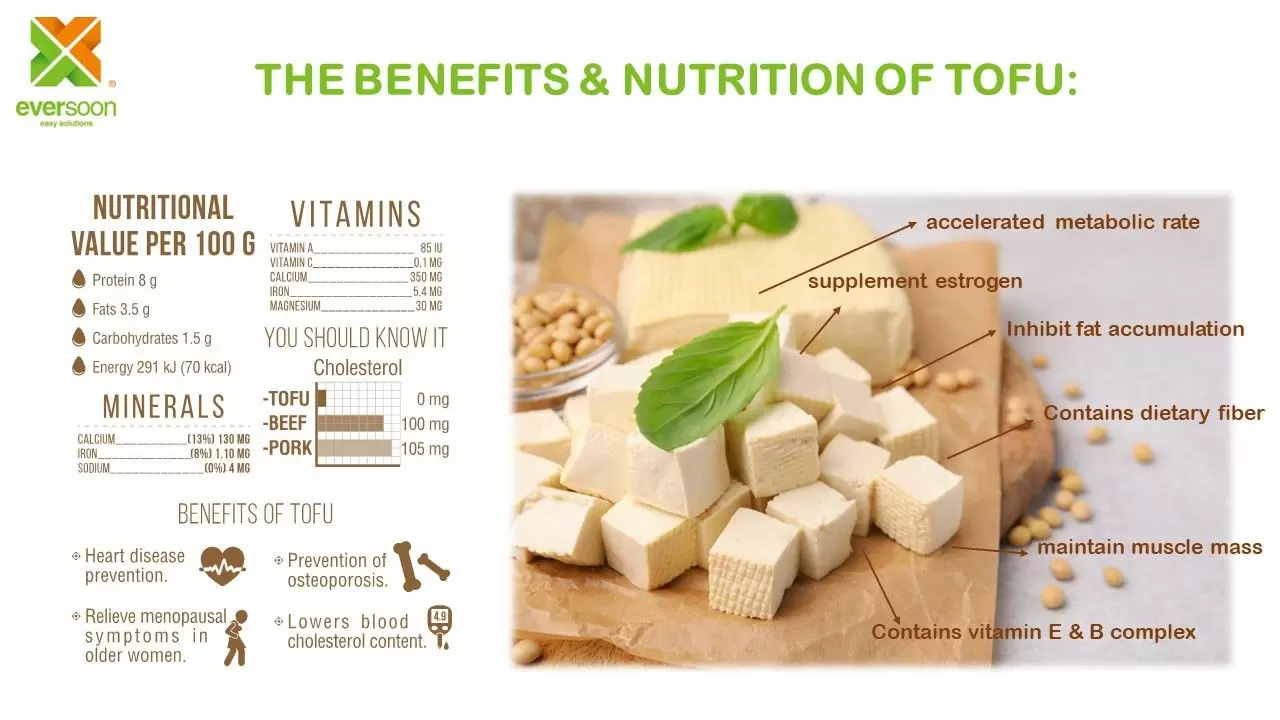

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

Benefits And Nutrition Of Tofu

Canada Food Guide Changes: More Veg, Less Meat, And No More Eating Alone

- Related Products

-

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

Automatic Soybean Soaking & Washing Equipment: Boost Tofu & Soy Milk Yields | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.