The Complete Guide to Choosing the Right Tofu Maker for Your Production

The Complete Guide to Choosing the Right Tofu Maker for Your Production

The Complete Guide to Choosing the Right Tofu Maker for Your Production

Whether you’re making tofu at home or running a full-scale factory, choosing the right tofu maker is key. Let’s explore how YSL Food’s Easy Tofu Maker helps you turn soybeans into perfectly crafted tofu.

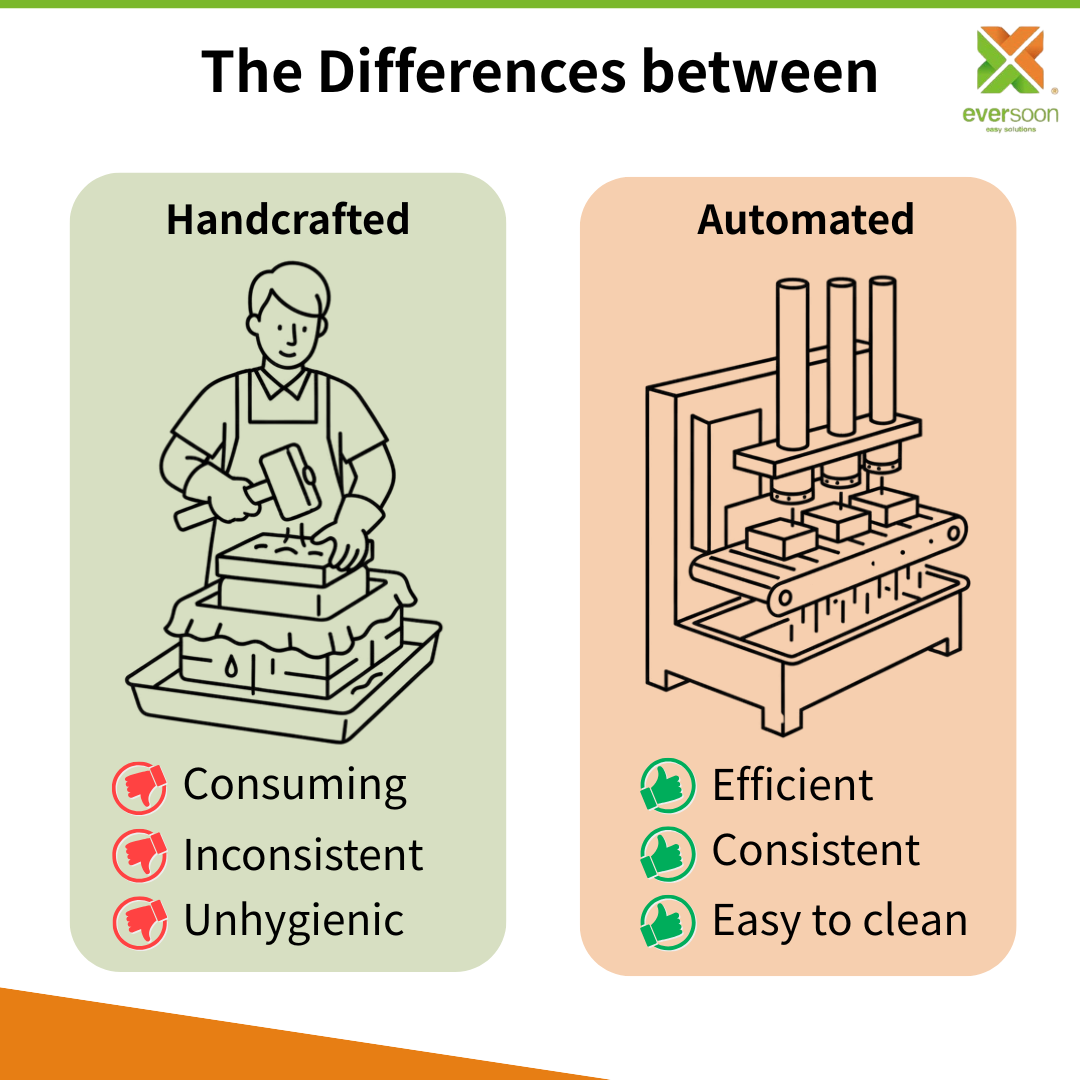

What Is a Tofu Maker and How Does It Work? A tofu maker is an automated system that turns soybeans into tofu through steps like soaking, grinding, heating, and pressing. It controls temperature and timing to ensure consistent texture and taste while improving hygiene and efficiency. By combining traditional craft with modern technology, tofu makers make high-quality tofu production faster, safer, and more reliable.

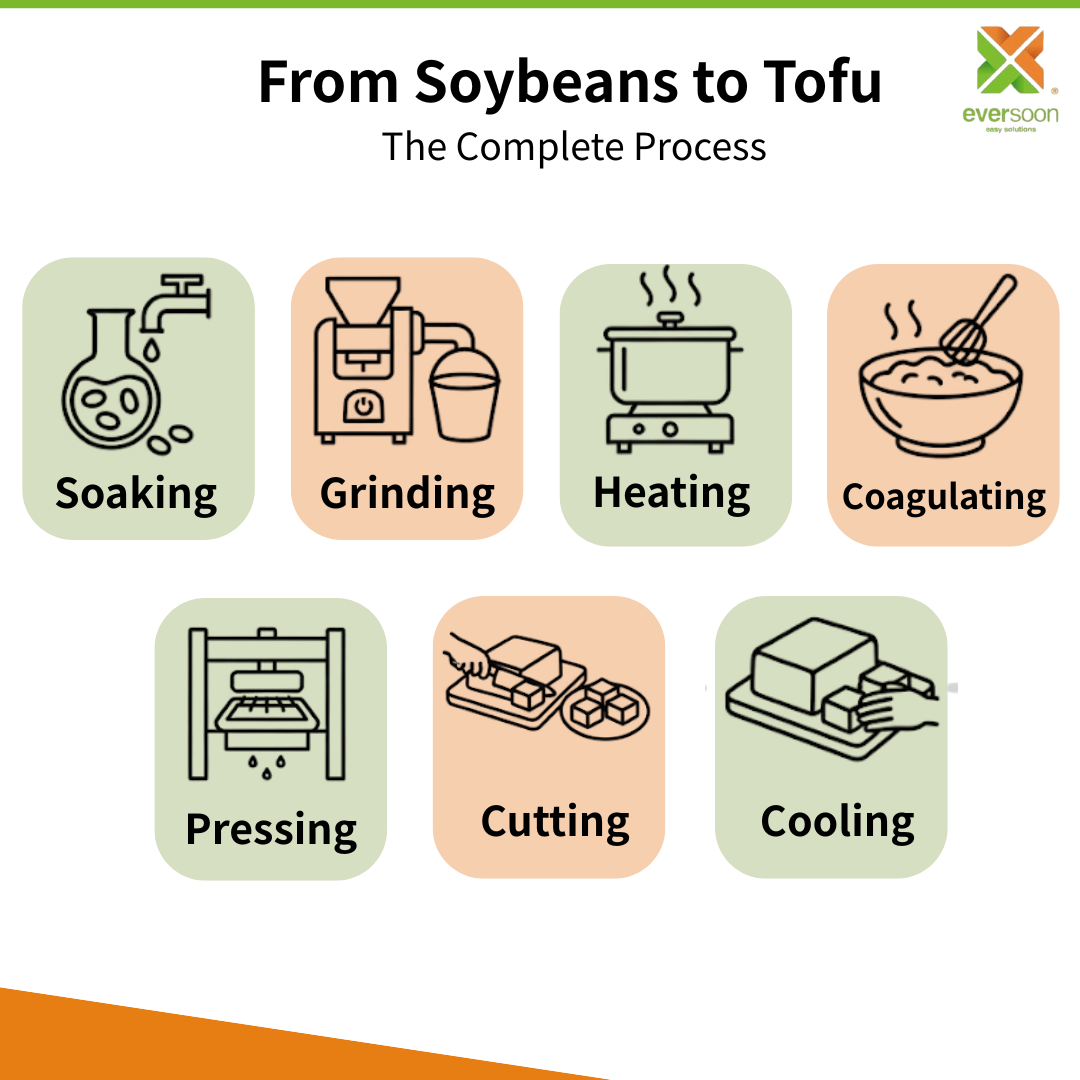

1. From Soybeans to Tofu – The Basic Process

(1). Soaking – Clean and soak soybeans in water until they soften and expand. This helps grinding efficiency and improves soy milk extraction.

(2). Grinding – Soaked beans are ground with water (about 1:9–10 ratio) to release proteins and fats, forming raw soy milk. The mixture is then filtered to separate okara (soy pulp).

(3). Heating – The raw soy milk is heated to about 85°C to remove the raw taste, sterilize, and denature proteins, ensuring safe and smooth soy milk.

(4). Coagulation – After cooling slightly, coagulant (such as nigari, gypsum, or GDL) is added to form soft tofu curds. Each coagulant creates a different texture and firmness.

(5). Pressing – The curds are poured into molds, pressed to remove excess water, and shaped into tofu blocks. Pressure and time are adjusted by tofu type.

(6). Cutting – Tofu is cooled, cut, and packaged (vacuum, nitrogen, or water-filled). Refrigerated tofu lasts 5–7 days; sterilized products can last for months.

Modern tofu lines use automated control and CIP cleaning systems for stable quality, hygiene, and high efficiency, enabling diverse products like tofu pudding, silken, or firm tofu.

2. Why Modern Tofu Makers Matter for Efficiency and Hygiene

Modern tofu makers elp producers create consistent, high quality results with far less manual effort. Automated controls reduce contamination risk, make better use of water and energy, and significantly shorten production time. Built with stainless steel and food grade material, these machines keep every step clean and safe. With precise programming, they ensure that the batch strikes the perfect balance between softness and firmness.

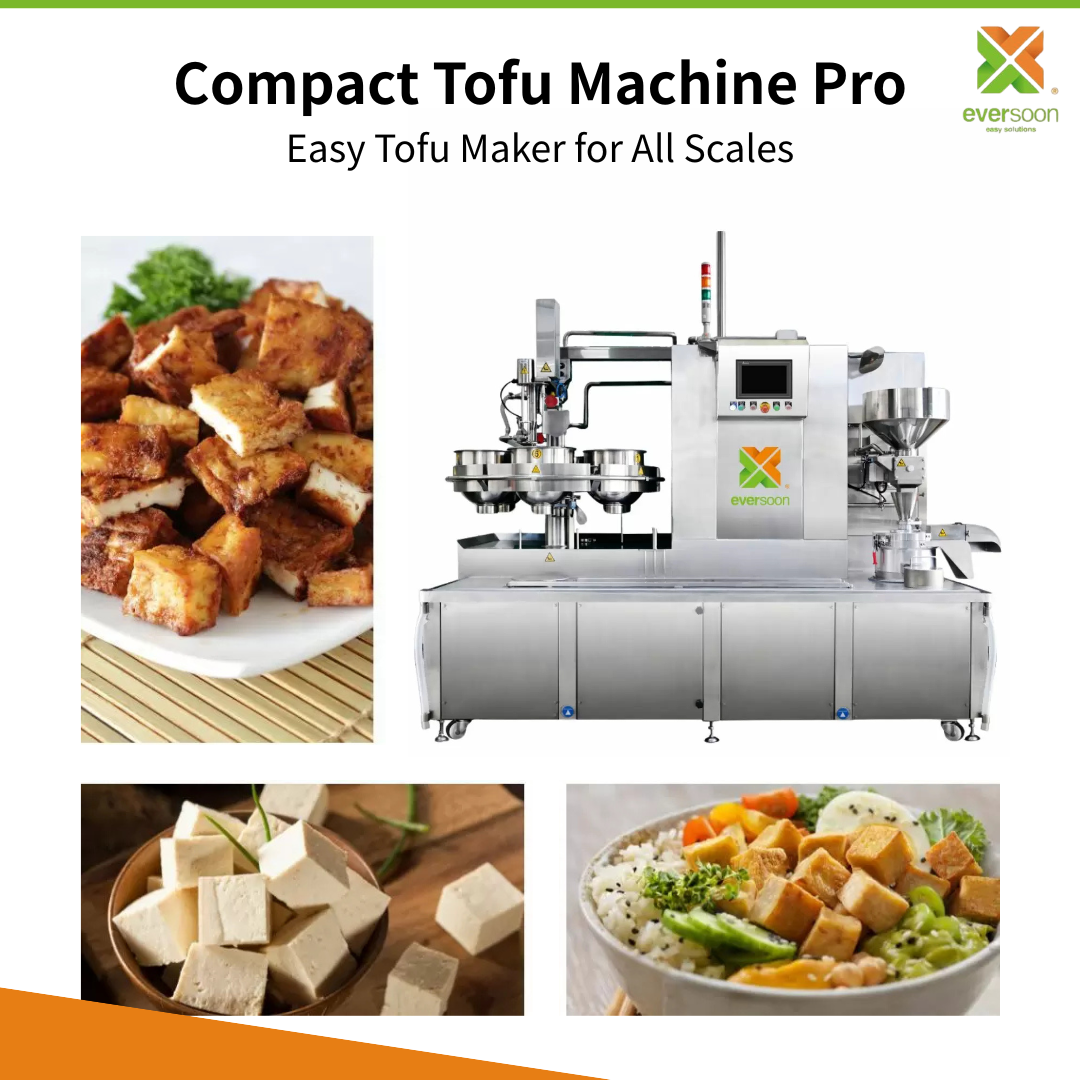

3. Overview of Compact Tofu Machine Pro Capabilities

Compact Tofu Machine Pro from YSL Food is built to make tofu production simple and flexible. With one compact machine, you can make soy milk, tofu pudding, silken tofu, firm tofu, and even dried tofu. All in the same system. Switching between products is quick and easy, so it’s perfect for producers who want to offer a wider variety without adding more equipment or complexity. YSL Food’s Compact Tofu Machine Pro is designed to make tofu production simple, stable, and flexible. Built with a continuous cooking system, it ensures even heating and complete protein conversion, giving every type the right texture and taste.

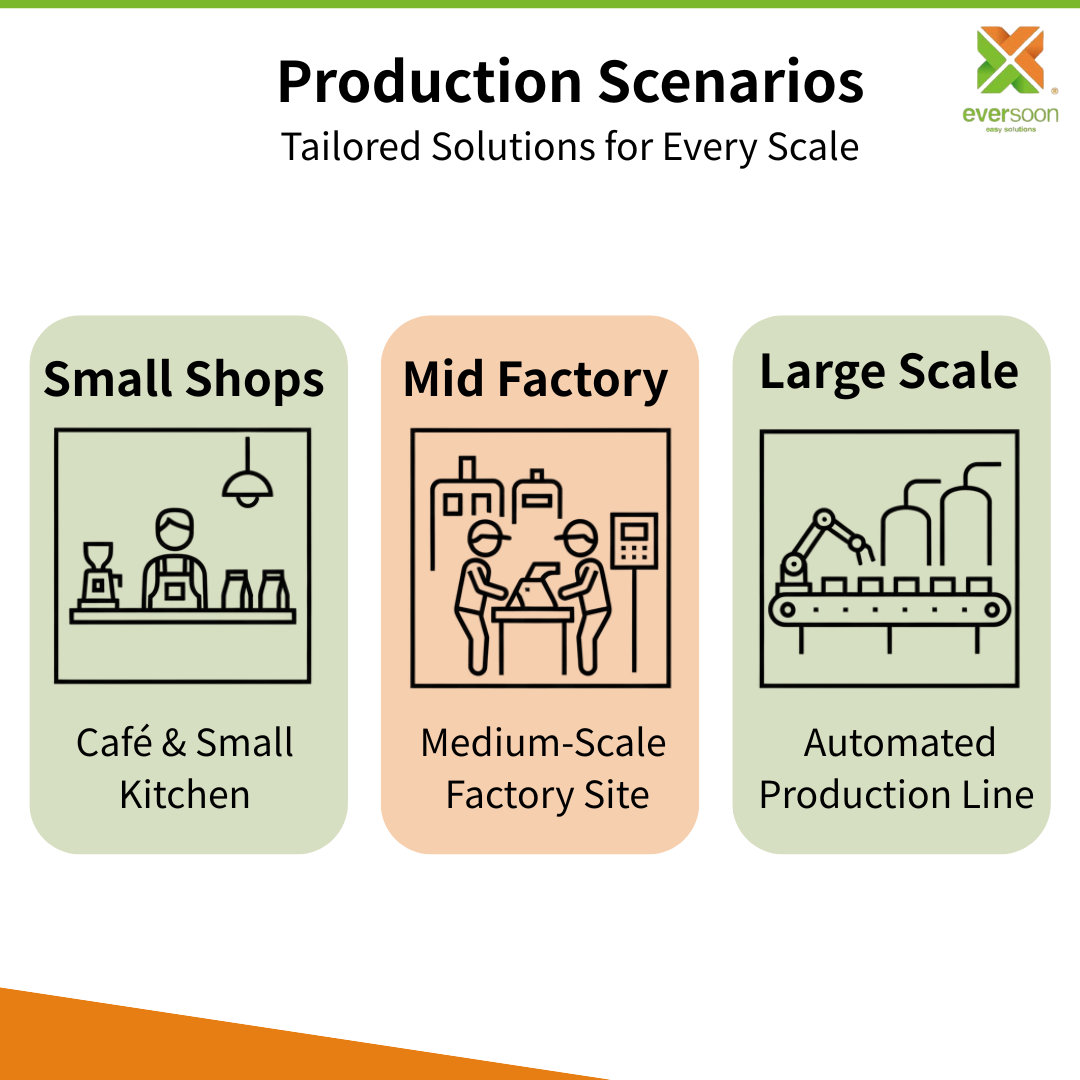

Easy Tofu Maker-Compact Tofu Machine Pro for Different Production Scenarios

Whether it’s a cozy tofu shop or a high-volume food factory, YSL Food’s Compact Tofu Machine Pro adapts flawlessly to different production needs. Built for flexibility, it allows users to make fresh tofu, soy milk, and tofu pudding on demand.

1. Small Shops and Restaurants (Local Production) For small tofu shops, local producers, cafés, and vegetarian restaurants, the Compact Tofu Machine Pro offers a space-saving solution for making fresh, handcrafted tofu right on-site. Compact Tofu Machine Pro can produce 30-40kg tofu per hour. It ensures a consistent texture and flavor while simplifying daily production. With its user-friendly operation, you can easily prepare soy milk, tofu pudding, or experiment with new recipes, flavors, and premium tofu desserts. All from a single, compact system.

2. Mid-Sized Food Factories and OEM Clients For regional producers or OEM partners, YSL Food offers customizable tofu systems with higher capacity and stability. Automation reduces manual work while maintaining product quality, ideal for brands expanding their tofu lines or developing plant-based food innovations. Clients across Europe and Asia use this easy tofu maker to scale up production efficiently while preserving artisanal quality.

3. Educational and R&D Centers (Teaching and Innovation Applications) The Compact Tofu Machine Pro is also highly favored by colleges, culinary schools, and food R&D centers. It helps students and researchers easily understand the tofu-making process, conduct coagulant testing, plant protein applications, and product development experiments. With its transparent operation and compact design, it’s ideal for demonstrations, hands-on workshops, and innovative research projects.

Key Features of the Easy Tofu Maker-Compact Tofu Machine Pro

YSL Food’s Compact Tofu Machine Pro combines craftsmanship and automation to bring precision, efficiency, and flexibility to tofu production.

(1). Multifunctional Production – From soy milk and tofu pudding to silken, firm, and dried tofu. One machine does it all. The easy tofu maker-Compact Tofu Machine Pro gives producers the flexibility to diversify their offerings without adding extra equipment or complexity.

● Customer Story – Latvia: From Handmade to Scalable Production. For four years, a small tofu shop in Latvia made tofu by hand with great care. As orders grew, it became hard to keep up. After choosing the Compact Tofu Machine Pro, they kept the same handmade quality but made tofu three times faster.

(2). Compact Design and Easy Operation – Its space-saving structure fits perfectly in small kitchens or production areas. With a clear touchscreen interface and intuitive controls, anyone can master tofu production with just a few steps.

● Customer Story – Germany: Family-Owned Vegan Brand. A vegan couple in Germany used to buy tofu from others and add their own sauces. They wanted to control quality from the start, so they came to Taiwan, where tofu is as common as bread. With the Compact Tofu Machine Pro, they now make fresh tofu every day — full of pride and consistency.

(3). Stainless Steel Construction & Food-Grade Materials – Made with SUS304 stainless steel, every surface is hygienic, durable, and easy to clean. It’s built for long-term use and meets the strict standards of modern food production environments.

● Customer Story – Taiwan: Supermarket Fresh Tofu Corner. A local supermarket in Taiwan wanted to offer customers fresh, house-made tofu. They installed the Compact Tofu Machine to produce and sell tofu directly in-store. The live production attracted shoppers, boosted trust, and increased sales — turning fresh tofu into a signature highlight of their brand.

(4). Energy-Saving and Easy Maintenance – An optimized heating system ensures stable performance while reducing energy consumption. The machine’s design allows for quick cleaning and minimal maintenance, keeping operations efficient and cost-effective.

(5). CE / ISO / Certified – Compact Tofu Machine Pro is fully compliant with CE, ISO, and HACCP certifications, giving producers peace of mind that every batch meets international safety and quality standards.

Step-by-Step Tofu Production Process

(1). Soaking and Grinding – Clean soybeans are soaked until soft, then ground with water into a smooth slurry—the base for soy milk. Modern tofu makers, like Compact Tofu Machine Pro, automate this step for consistent texture.

(2). Heating and Coagulation – Soy milk is heated to remove the raw flavor, then a coagulant (nigari, gypsum, or other solutions) is added to form curds. Compact Tofu Machine Pro ensures even coagulation and stable texture.

(3). Pressing and Molding – Curds are pressed into molds to remove excess water. Light pressing produces silken tofu; firmer pressing yields block or dried tofu. Adjustable machines maintain consistency batch after batch.

(4). Cooling and Cutting – Tofu blocks are cooled to set their shape and retain moisture, then cut into desired sizes for retail or culinary use.

(5). Packing and Storage – Finally, tofu is packaged hygienically for refrigeration or freezing, ready for distribution or consumption. Automation reduces contamination risk and ensures safety.

Why Choose YSL Food as Your Tofu Maker Manufacturer

(1). 30+ Years of Food Machinery Expertise – With over three decades of experience in food machinery, YSL Food has mastered the art and science of tofu production. From small workshops to large-scale factories, our machines are designed for efficiency, hygiene, and consistent quality.

(2). Global Installations – YSL Food’s tofu machines are trusted worldwide. Examples include Germany, USA, Switzerland, Singapore, Canada, Austria, Malaysia, and France. From Europe to Asia and the Americas, YSL Food machines support diverse production needs, from small boutique brands to industrial-scale manufacturers.

(3). Reliable After-Sales Service and Customization – We don’t just deliver machines. We deliver confidence. Our global support network ensures fast, professional service whenever needed. Customization options let you adapt machines to your production goals. Along with CE / ISO / HACCP certified equipment, our solutions reflect YSL Food’s commitment to quality, reliability, and sustainability.

FAQ – Everything You Need to Know About Tofu Makers

Q1. What types of tofu can the Compact Tofu Machine Pro Easy Tofu Maker produce? It can produce a wide range of products, including soy milk, tofu pudding, silken tofu, firm tofu, and dried tofu, all from the same compact system.

Q2. What is the production capacity per hour? Capacity depends on the selected model and recipe. From small shop setups to 450KG industrial lines, YSL Food offers tofu makers that fit every production scale.

Q3. Does it require special training to operate? Not at all. Compact Tofu Machine Pro features a touch-screen control panel with intuitive settings. Most operators can get started after a brief training session.

Q4. How long is the warranty? All machines come with a one-year warranty covering key components. YSL Food also provides lifetime technical support and spare parts service.

Q5. What certifications does it have? YSL Food machines are built with CE, ISO, and HACCP certifications, ensuring safety, hygiene, and global production compliance.

Ready to Start Your Tofu Production? Looking to start or scale your tofu business? Contact YSL Food to discover how Compact Tofu Machine Pro can transform your production line. [📩 Get a Quote] [📄Download Brochure]

Hot articles

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

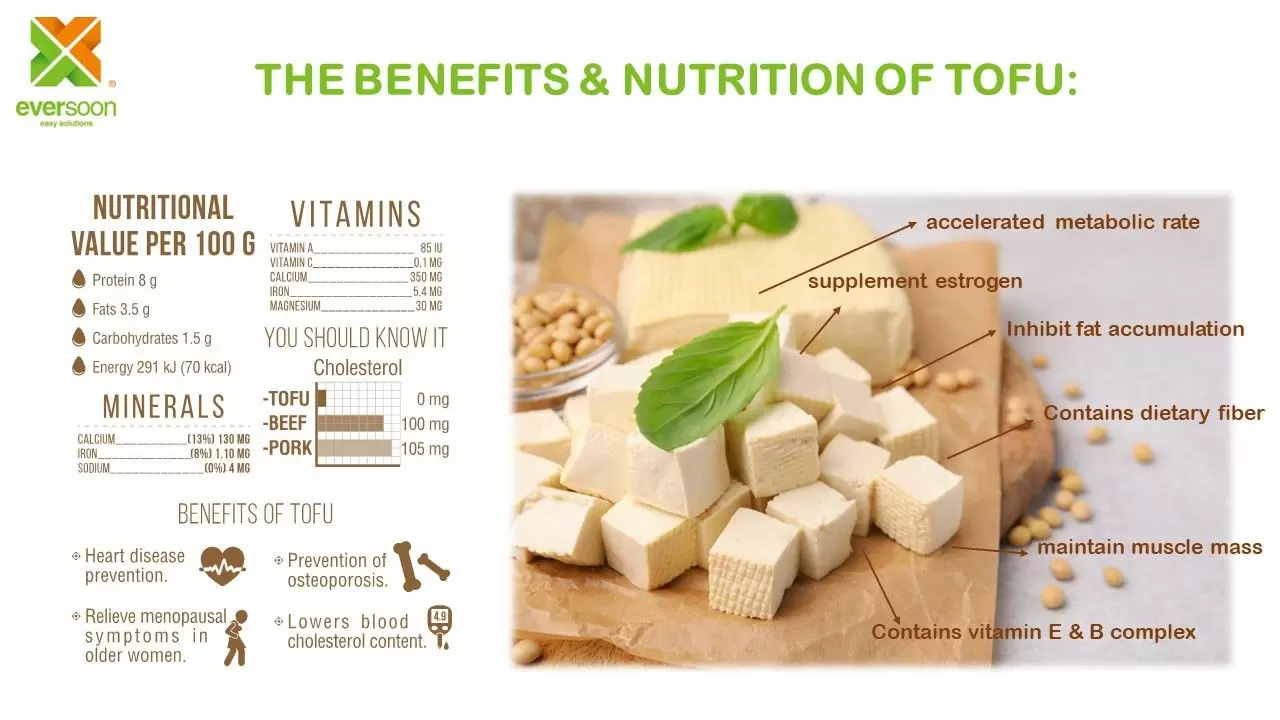

Benefits And Nutrition Of Tofu

Canada Food Guide Changes: More Veg, Less Meat, And No More Eating Alone

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

The Complete Guide to Choosing the Right Tofu Maker for Your Production | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.