Continuous Type Automatic Soymilk Cooking Equipment

Automatic Soymilk Cooking Equipment

Yung Soon Lih Food Machinery's cooking equipment is equipped with automatic temperature and pressure monitoring device, which can automatically reduce temperature and pressure. This continuous cooking equipment does not require defoamer to remove the soymilk foam, so that the soymilk and tofu retain their natural ingredients, so that you can maintain your health and replenish the rich nutritional proteins of soymilk and tofu.

【Why do we need continuous automatic cooking system?】

With global warming and increasing changes in the human living environment, people are gradually making changes in their daily diets, coupled with the rise in health awareness, leading to an increased reliance on plant-based proteins, resulting in an increasing demand for soymilk, even greater than the supply. Soy products are replacing meat products. You may not realize it, but vegan meat is a delicious and nutritious soy product made from soybeans through a number of processing procedures! Soy products contain plant-based proteins. Cooking the milk is an important factor in making soymilk more flavorful and tastier.

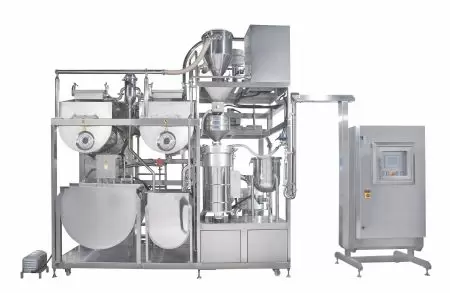

【Feature of continuous automatic cooking system】

1. Self-circulating cleaning on the cooking system:The 2-inch soymilk steam mixing pipe and thermal pipe design of the boiler line cleaning cycle, along with the high speed centrifugal pump, ensures that the flow rate of the self-circulating cleaning is sufficient to cause turbulence and friction to the pipes, removing sticky proteins to ensure cleanliness.

2. International brand steam proportional valve: control the amount of steam injected into the soymilk, together with the temperature control sensor, the temperature of the soymilk rises step by step to ensure the precise temperature of the cooked soymilk.

3. Keep-warm pipe to stabilize cooked soymilk: Keep-warm pipe adopts the design of increasing the keeping-warm time to stabilize cooked soymilk to ensure that the temperature of soymilk rises step by step to ensure that soymilk is cooked.

4. Flexible design of steaming according to customer's demand: The independent steaming line design can flexibly design the steaming volume according to customer's demand, and can provide up to 8000L of steaming volume per hour.

5. Pressure relief tank for safety

6. Hygienic design for safety and protection : The main design is EHEDG SUS304 with safety protection, easy to clean with high pressure water, strong and durable.

7. Smaller size, less space required

【Application of Yung Soon Lih automatic cooking equipment】

Tofu products are available in a wide variety of flavors, including tofu sandwiches, tofu burgers, tofu pizzas, tofu BBQ, tofu steaks, tofu salads, and silken and firm tofu. The seasoned flavor can be similar to plant-based meat, more in line with the nutritional value ! How to produce tofu and how to replace meat with firm tofu, we have prepared a set of SOPs for you and propose effective improvements and solutions for the market.

Features

- Pump start time, can be set to pumping time to start

- Pumping time: set the arrival time of the pulp in each heating section of the cooker

- Cooking temperature: set the heating temperature of each heating section of the cooker

- Drainage back pressure setting: able to set drainage of back pressure, ensure product cooked well during the pipe

- Able to setting postpone stop machine time when reach to high level

- Able to set postpone start time when lower high level

- Able to set cooked pump frequency

- Start time on SIP uncooked soymilk pump

- Able to set cooking machine start SIP cleaning time

- Independent cooking pipeline design, flexible to design the cooking capacity depending on customer needs

Specification

- Customized design according to customer's capacity requirements

Applications

Application of automatic cooking equipment

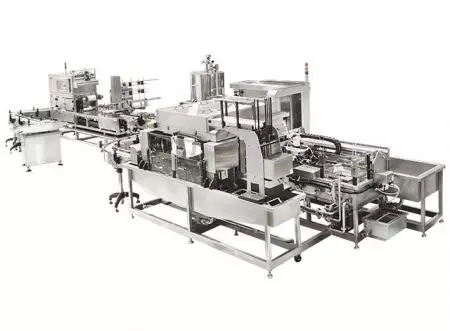

Different kinds of tofu have different texture, firmness and different meal application on your table, Yung Soon Lih-cooking system is able to sociable with optional device to produce different kinds of tofu.

Services

Yung Soon Lih (eversoon) Food Machine provides 24-hours online consultation, cooperates with engineers to solve customers’ problems by remote operation, saves people's round-trip time and labor cost, and solves customer problems in a timely and rapid manner.

In addition, food equipment who just started their business or expanded their factories, our senior engineers will go to the company site to survey and help you to plan the layout. In the past 36 years, We had built up a good partnership with our global customers like the Czech Republic, Poland, Canada and also transferred the technical know-how of producing soy milk and tofu to our customers. We were committed to becoming a turnkey solution provider.

- Movies

- Related Products

Automatic Tofu Coagulation Equipment

The automatic coagulating machine can reduce manpower and improve the efficiency of the tofu...

Details Add to ListDouble Line Double Grinding Deslagging Equipment

Double line double grinding and dregs removal system has four grinding and dregs removal machines,...

Details Add to ListContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt...

Details Add to ListAutomatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which...

Details Add to ListAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu...

Details Add to List- Files Download

Continuous Type Automatic Soymilk Cooking Equipment - Automatic Soymilk Cooking Equipment | Taiwan-Based Soybean Processing Equipment Manufacturer Since 1989 | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a Continuous Type Automatic Soymilk Cooking Equipment manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

We are the first food machine manufacturer whom developed the European Tofu turn-key production line, which can produce Asian Tofu, and Soy Milk processing equipment. Our tofu production machines are specially design and able to produce Tofu Burger, Vegetable Tofu, Smoked Tofu, Tofu Sausage to satisfy consumers' demand from the American and European market.