The Complete Guide to Using a Tofu Press (and When to Upgrade to an Easy Tofu Maker)

The Complete Guide to Using a Tofu Press (and When to Upgrade to an Easy Tofu Maker)

The Complete Guide to Using a Tofu Press (and When to Upgrade to an Easy Tofu Maker)

Tofu pressing plays a key role in achieving the right texture and flavor. This guide explores how tofu presses work, their materials and functions, and when it’s time to upgrade to an Easy Tofu Maker for better consistency and efficiency.

What Is a Tofu Press and Why Do You Need One?

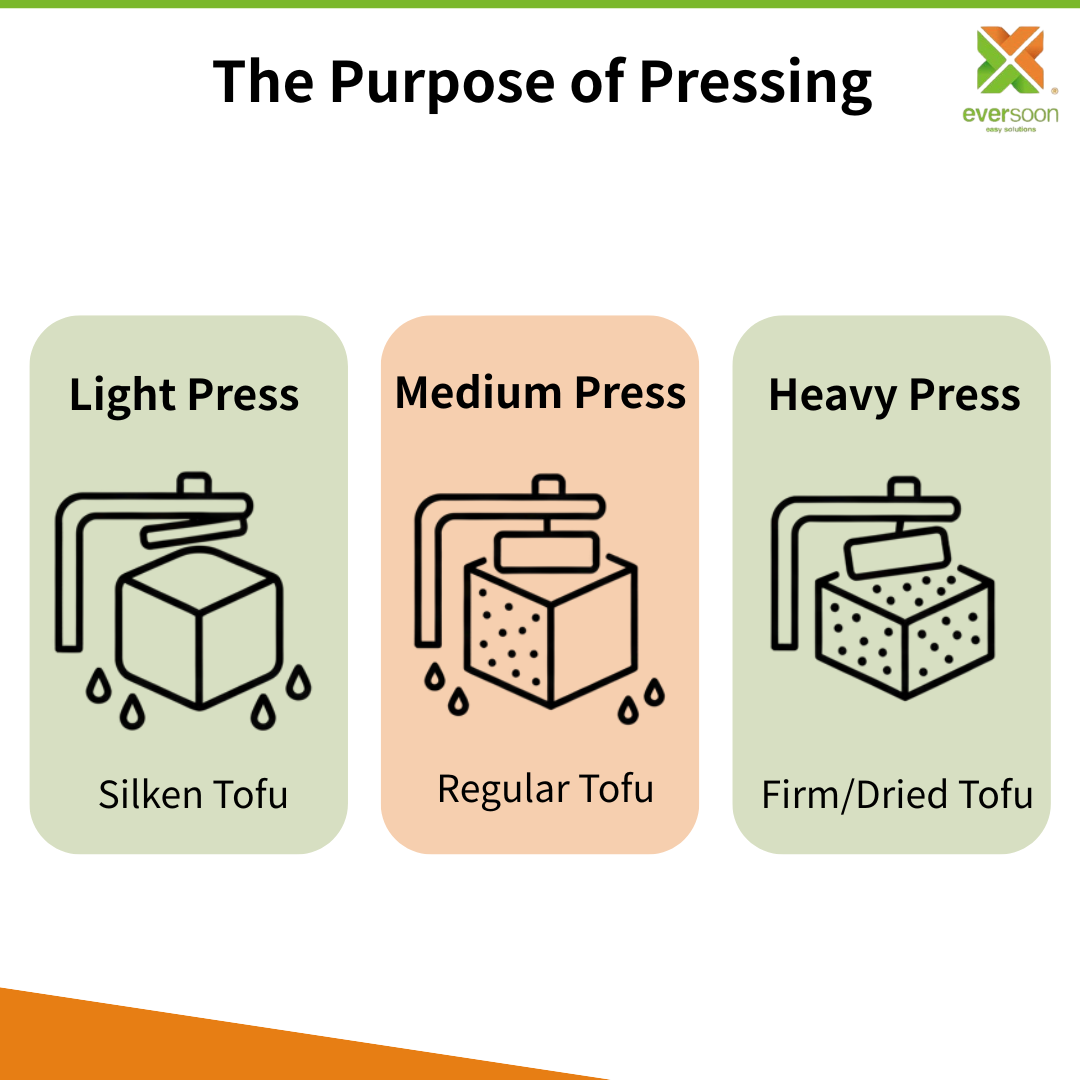

A tofu press shapes soft soybean curds into firm, uniform blocks by removing excess water after coagulation. The pressure and time determine firmness from silky soft to extra firm—making this step key to texture and flavor control.

1. The Purpose of Pressing Tofu

A good tofu press improves texture, flavor absorption, and consistency across every batch.

(1) Texture

Pressing ensures structural integrity, so tofu maintains its form during cooking, frying, or marinating.

(2) Flavor absorption

Removing excess water creates microscopic spaces within the tofu, allowing sauces and seasonings to penetrate more deeply.

(3) Consistency

Mechanical pressing provides uniform pressure and timing, resulting in tofu with even density and a professional, clean appearance.

Manual tofu presses use weights or screws, so pressure varies by batch. This can cause uneven texture and lower yield, especially for small or growing producers.

3. Common Materials (Mesh Plates vs. Tofu Cloth)

| Type | Ideal For | Pros | Cons |

|---|---|---|---|

| MESH Plate | Automated or large-scale production | Labor-saving, allows direct forming and demolding | May leave texture marks, less smooth surface |

| Tofu Cloth (Wrapping Cloth) | Premium or handmade tofu | Smooth, fine tofu surface | Time-consuming, requires manual wrapping/unwrapping |

Mesh plates are labor efficient. They allow direct forming, pressing, and demolding, making them ideal for automated or large-scale production.

Tofu cloths (wrapping cloths) require manual wrapping and unwrapping for each batch, which is more time-consuming and labor-intensive. However, they produce tofu with a smoother and finer surface, making them preferred for premium or handmade tofu products.

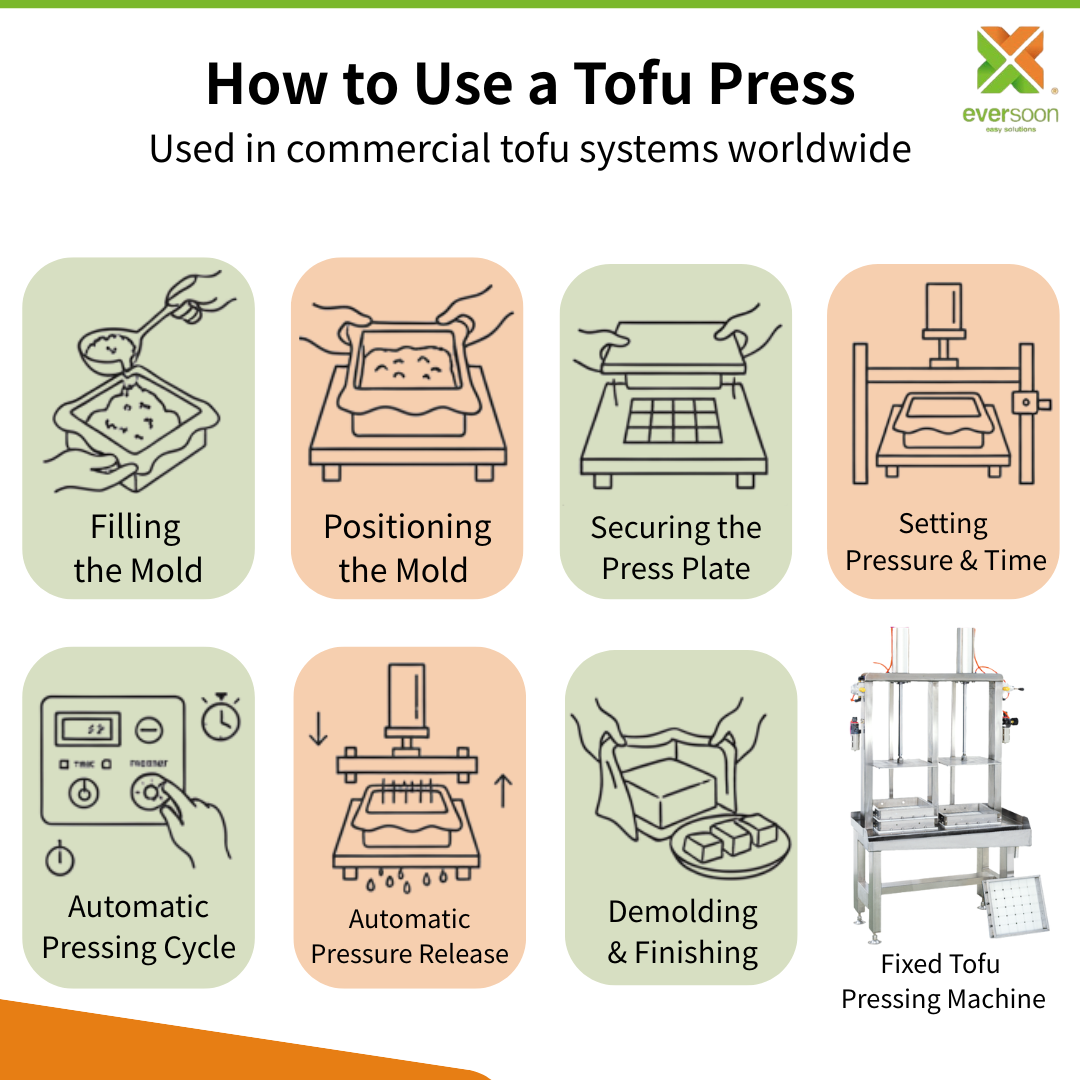

How to Use a Tofu Press (Step-by-Step Guide)

Pressing tofu may look simple, but consistent texture depends on timing and pressure control. Here’s how the process works using a pneumatic tofu press—the same principle used in many professional tofu systems.

1. Step-By-Step Process (Example: Pneumatic Tofu Press)

- Filling the Mold

Place the coagulated soy curds (tofu pudding) into a clean filter cloth and mold. - Positioning the Mold

Set the filled mold on the press table, ensuring it’s properly aligned and level. - Securing the Press Plate

Close and lock the press plate to keep the mold in position. - Setting Pressure and Time

Adjust the control panel to your preferred pressing force and duration. - Automatic Pressing Cycle

Start the process; the pneumatic cylinder applies steady pressure while the timer monitors each stage. - Automatic Pressure Release

When the timer ends, the system releases pressure and raises the plate automatically. - Demolding and Finishing

Open the mold and remove your perfectly shaped tofu, ready for cooling or cutting.

2. Perfecting Your Tofu Press – Pro Tips!

Tofu quality depends on controlling pressure and time. Too much pressure too soon can make tofu hard or cracked, while too short a pressing time leaves it wet and soft.

Start with low pressure for 1–2 minutes, then gradually increase, keeping drainage holes clear for even water release and smooth texture.

Manual vs. Automatic: Which Tofu Press Is Right for You?

| Type | Ideal For | Pros | Cons |

|---|---|---|---|

| Manual Weight Press | Home or traditional tofu shops | Low cost, easy setup | Labor-intensive, inconsistent results |

| Manual Press Table (Single/Double/Triple) | Small tofu shops | Adjustable pressure, stable results | Limited capacity, requires operator |

| Continuous Tofu Pressing Machine | Large-scale tofu factories | Fully automated, high efficiency, consistent quality | Higher investment, not for small-scale setups |

Key Point:

Easy Tofu Maker (Compact Tofu Machine) is a semi-automatic system that combines grinding, cooking, and pressing in one unit — ideal for restaurants and small food factories.

It allows producers to efficiently make a variety of soy-based products with consistent texture, high hygiene standards, and minimal manual labor — ideal for commercial kitchens, restaurants, and food factories.

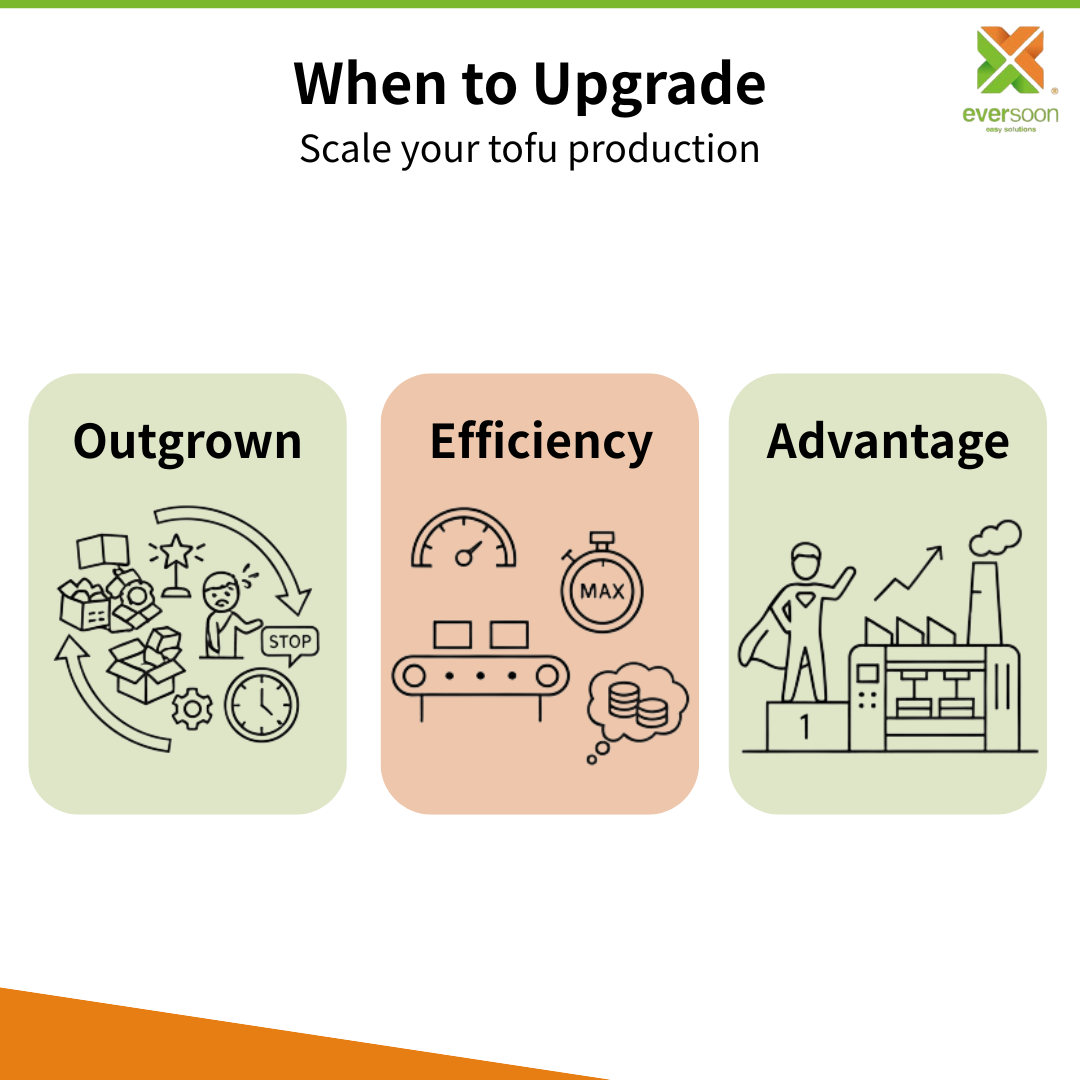

When to Upgrade from a Manual Tofu Press to a Professional Machine

1. Signs You’ve Outgrown a Home Tofu Press

- You need consistent tofu texture and firmness for multiple batches.

- Production volume exceeds what manual pressing can handle.

- You want to reduce labor and avoid batch-to-batch variations.

2. Efficiency and Hygiene in Commercial Settings

Commercial operations demand stable results, uniform shape, and lower contamination risk. Automatic pressing ensures each tofu block has precise water content, consistent texture, and minimal breakage.

3. The Easy Tofu Maker Advantage – One Machine, Multiple Products

Unlike small home tofu presses that handle only basic tofu, Easy Tofu Maker offers multifunctional production for silken tofu, firm tofu, tofu pudding, dried tofu, and soy milk.

Its semi-automatic pressing system ensures consistent texture, better yield, and hygienic operation — bridging the gap between manual tools and full-scale tofu production lines.

Comparison: Manual vs. Automatic Pressing Quality Differences

| Comparison Criteria | Manual Press | Automatic Press |

|---|---|---|

| Pressure Stability | Depends on operator, inconsistent | Programmable, stable pressure |

| Water Content Control | Hard to repeat accurately | Precise control over firmness and moisture |

| Appearance Consistency | Uneven edges, irregular shape | Uniform, neat blocks |

| Yield & Waste | Prone to cracking or misshapen tofu | High yield, low breakage |

| Texture Consistency | Slight variations per batch | Consistent batch-to-batch quality |

Key Takeaway:

Upgrading to an automatic system like Easy Tofu Maker transforms tofu production — from unpredictable, labor-intensive manual pressing to standardized, hygienic, and scalable commercial output.

Why Choose YSL Food

1. 30+ Years of Experience in Soybean Food Machinery

YSL Food has over three decades of experience designing and manufacturing soybean food equipment. From traditional tofu presses to fully automated tofu production lines, our expertise ensures reliable, high-quality solutions for every scale of production.

2. CE-Certified Equipment Exported to 50+ Countries

Our machines meet international CE standards and are trusted by clients in more than 40 countries across Europe, Asia, and the Americas. YSL Food helps producers worldwide achieve consistent tofu quality with safe and hygienic equipment.

[CE] [ISO] [Product Patent]

3. Professional After-Sales Support & Customization

We provide tailored support to meet your production needs. From installation and training to maintenance and custom modifications, our team ensures your tofu-making operations run smoothly and efficiently.

FAQ – Everything You Need to Know About Tofu Presses

1. What’s the difference between a tofu press and a tofu maker?

A tofu press is designed to remove water from coagulated soy curds, shaping tofu into firm blocks. A tofu maker, like YSL’s Easy Tofu Maker, combines soaking, grinding, and pressing in one automated system for consistent tofu production and multiple product types.

2. How long should you press tofu for?

Pressing time depends on the desired texture. Soft tofu needs only a short press, while firmer or dried tofu requires longer pressing and higher pressure. Automatic presses let you set precise pressure and timing for consistent results.

3. Can you make tofu without a press?

Yes, but you’ll need to manually drain excess water, which can be inconsistent and affect texture. Using a press ensures even water removal and a stable, sliceable tofu block every time.

4. Is an automatic tofu maker worth it for small shops?

For small shops, cafés, or vegetarian restaurants, automated systems like the Easy Tofu Maker save time, reduce manual labor, and produce consistent quality — making it easier to serve fresh tofu, soy milk, or tofu desserts daily.

5. How do I clean and maintain a tofu press machine?

Keep the press clean by rinsing all surfaces after use, removing leftover curds, and ensuring drainage holes are clear. Stainless steel models are easier to sanitize and maintain for long-term hygiene and durability.

Ready to Upgrade Your Tofu Press?

< img src="/Templates/pic/tofu-press-1015-qq.png" width="1920" height="470" alt="single-presser-of-tofu-pressing-machine-automation" title="Single presser of tofu pressing machine automation" />

Looking to save time and produce consistent, professional-quality tofu? Explore the Easy Tofu Maker by YSL Food — CE-certified, compact, and designed to handle everything from soy milk to silken and firm tofu with precision.

Hot articles

Forecast 2021-2026 tofu market and trends.

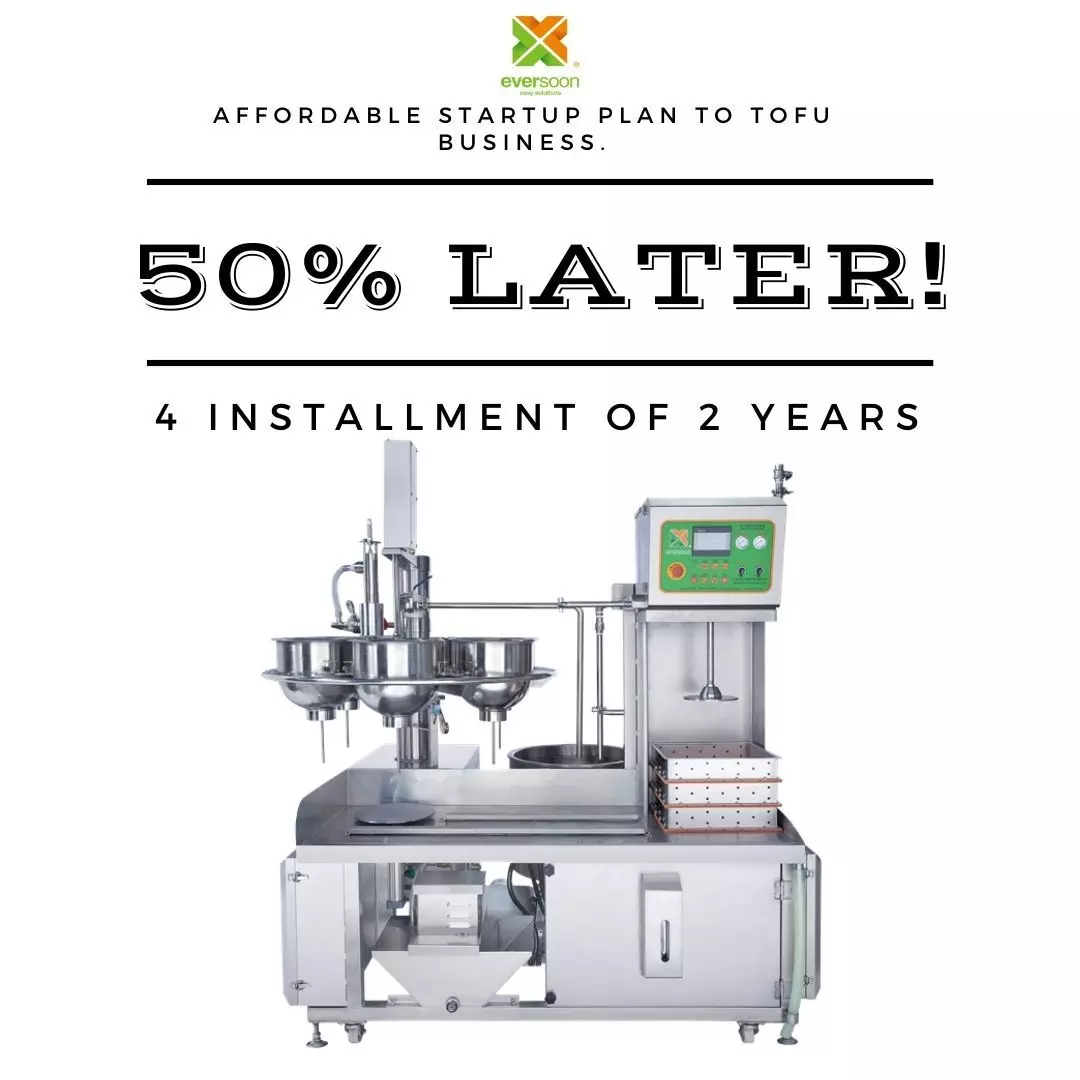

Affordable Startup Plan to Vegan Tofu Business

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

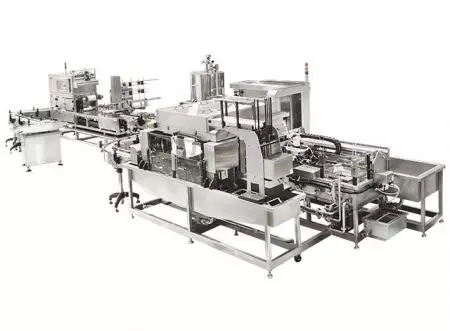

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

The Complete Guide to Using a Tofu Press (and When to Upgrade to an Easy Tofu Maker) | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.