Tofu Production Equipment: Leading the Trend in Healthy Eating in Europe

Tofu Production Equipment: Leading the Trend in Healthy Eating in Europe

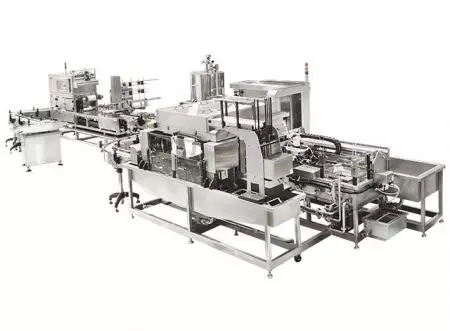

With the rise of plant-based diets, the demand for tofu in the European market continues to grow! Our tofu production equipment is designed for modern manufacturing, combining high-efficiency automation and eco-friendly concepts to help you capture the market quickly. Whether it’s production efficiency, product consistency, or environmental sustainability, our equipment offers comprehensive solutions to help you stand out in the competitive market!

Tofu Production Equipment: Leading the Trend in Healthy Eating in Europe

The Rise of Tofu Production in Europe

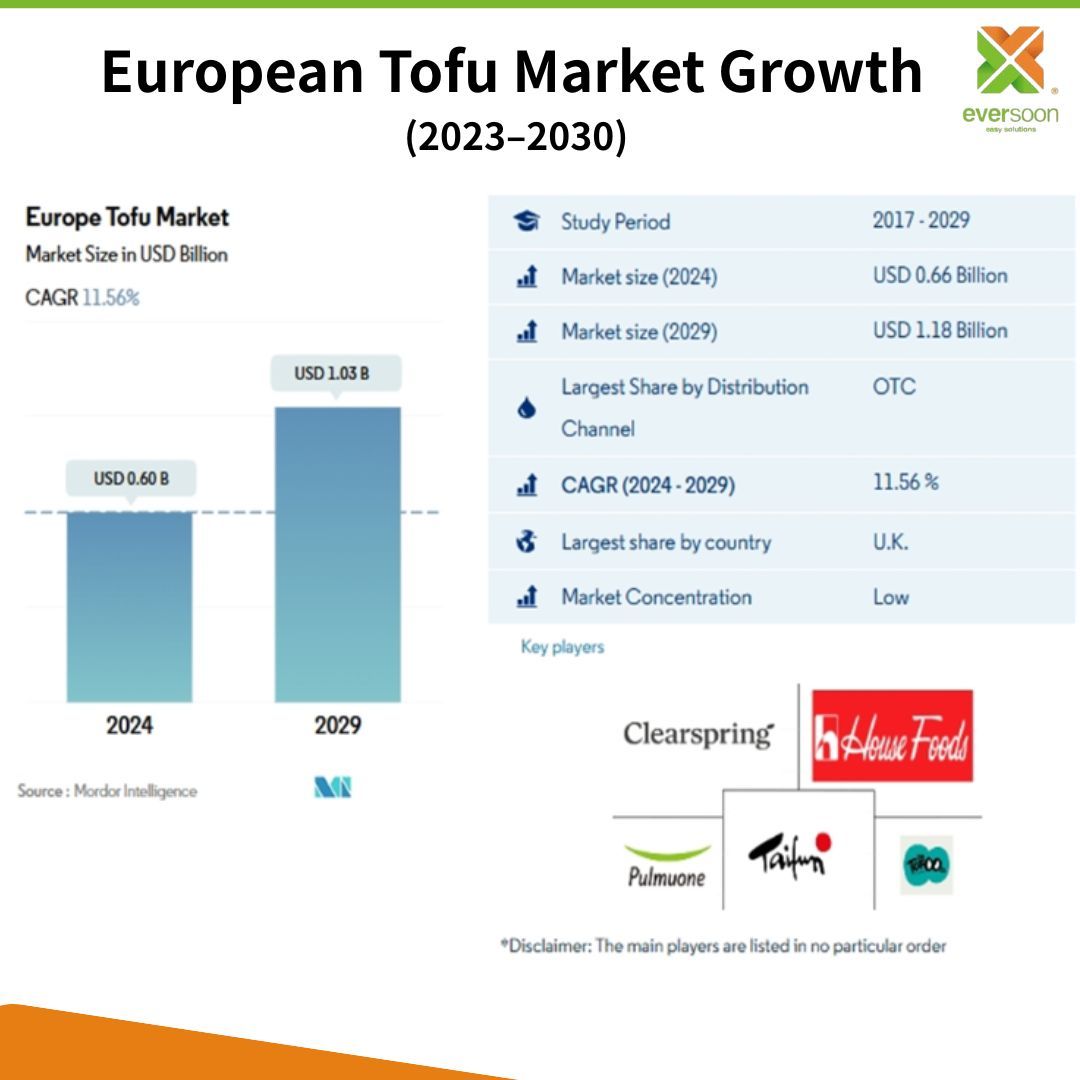

Across Europe, the plant-based boom is shifting from trend to long-term transformation. Consumers are actively looking for food choices that balance sustainability, nutrition, and taste—and tofu has rapidly become a core protein within this shift.

Recent market research indicates that the European tofu market is projected to grow at a CAGR exceeding 5% through 2030, fueled by the region's increasing focus on climate-friendly diets, wellness-driven lifestyles, and high-protein alternatives.

To support this momentum, Yung Soon Lih offers a complete range of tofu manufacturing solutions engineered for scalability, automation, and sustainability, enabling food producers to stay competitive in a fast-expanding market.

Why Choose Advanced Tofu Production Equipment

Modern tofu production requires more than traditional techniques—it demands technology that delivers precision, consistency, and operational efficiency at every stage. Our production systems are designed to help manufacturers optimize cost structures, strengthen product stability, and accelerate time-to-market.

Key Benefits:

- High Production Efficiency - Automated pressing, forming, and cutting systems enable continuous output with minimal manual intervention, ideal for factories scaling production.

- Consistent Product Quality - Real-time monitoring and precision control ensure uniform texture, firmness, and moisture levels across every batch.

- Energy-Saving & Sustainable - Optimized water and steam utilization reduces waste, supporting sustainability targets and lowering operational expenses.

- European Regulatory Compliance - Fully compliant with European food safety and export standards, allowing producers to enter new markets with confidence.

Meeting Europe's Demand for Plant-Based Foods

From Germany's growing vegan consumer base to France's flexitarian movement and the Nordic region's strong sustainability commitments, Europe's appetite for tofu is diversifying and accelerating.

Our production equipment enables manufacturers to develop a broad portfolio of tofu products - including silken, firm, pressed, dried, and flavored varieties—ensuring alignment with regional tastes and evolving market needs.

Factories can integrate our systems to streamline production, improve versatility, and respond quickly to new product development opportunities within Europe's expanding plant-based sector.

Ready to Modernize Your Tofu Production Line?

Future-proof your operations with advanced tofu production technology designed for efficiency, consistency, and sustainable growth.

Hot articles

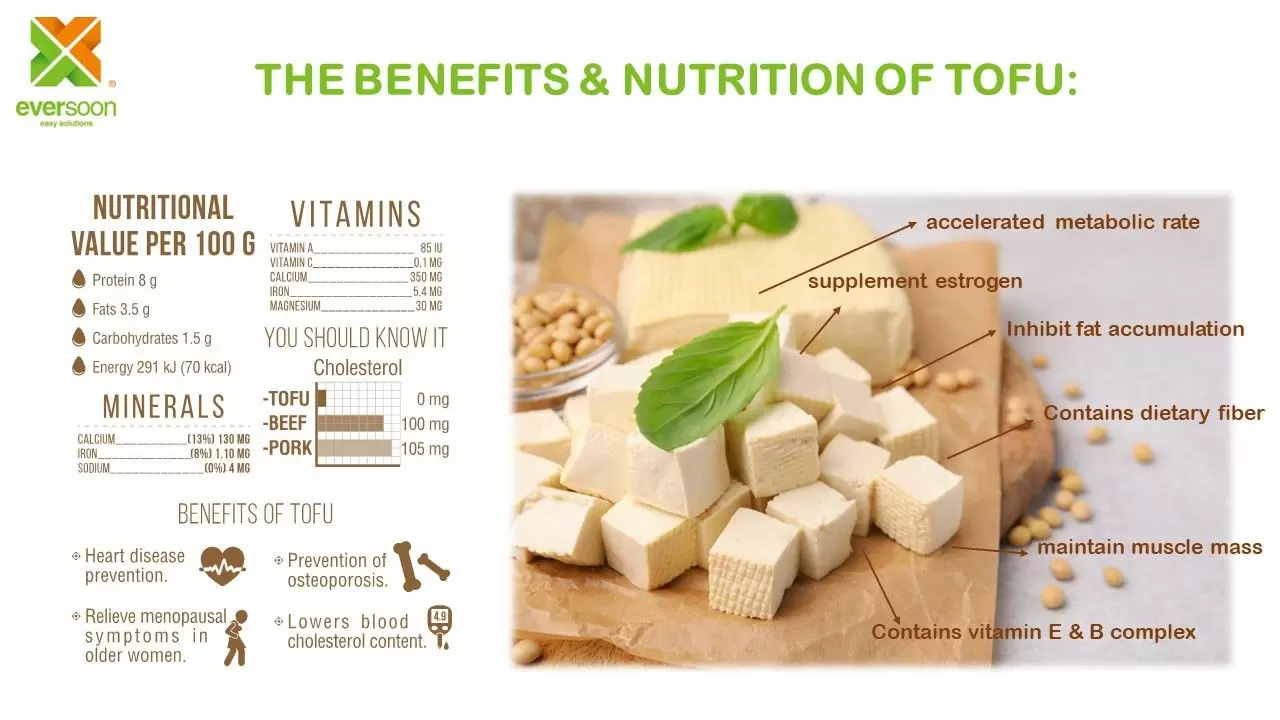

2020-2024 Health benefits of tofu will increase market demand

When is the best time to drink soy milk?

Benefits And Nutrition Of Tofu

Canada Food Guide Changes: More Veg, Less Meat, And No More Eating Alone

- Related Products

Automatic Tofu Cutting Equipment

Tofu Automatic Cutting Machine adopts three sections to detect the whole slab of tofu which is automatically introduced, the first section detects and cuts...

Details Add to cartAutomatic Cutting Equipment for Tofu in Water

After the operator pushes the unmolded tofu plate into the automatic cutting machine in tofu water, the machine is equipped with a conveyor belt that automatically...

Details Add to cartTofu Manual Cutting Equipment

In the early days, tofu manufacturers or tofu workshops used to cut tofu with a kitchen knife, which not only tested the master's knife skills over the years,...

Details Add to cartContinuous Tofu Pressing Machine

After the tofu molds are stacked and transported to the tofu press station, the conveyor belt of the tofu press is synchronized and the tofu molds are automatically...

Details Add to cartTofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The machine is manually operated, it is using the principle of lever to reduce the weight...

Details Add to cartsemi Auto.Tofu Mold Turning Machine

Pressed tofu mold can only be cut after removing the mold and cloth. The operator pushes the tofu mold into the tofu mold turning box to the end, presses...

Details Add to cart

Tofu Production Equipment: Leading the Trend in Healthy Eating in Europe | CE Certified Tofu Product Line, Soybean Soak & Wash Tank, Grinding & Cooking Machine Manufacturer | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a food manufacturing machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

Yung Soon Lih has more than 30 years of food machinery manufacturing and technical experience, professional production: Tofu Machine, Soy Milk Machine, Alfalfa Sprouts Germination Equipment, Grinding Machine, etc.