Compact Tofu Machine

Small Tofu Machine For Business

The Compact Tofu Machine has various functions such as grinding and separating machine, soymilk cooking machine, coagulating and curd breaking machine, and a tofu pressing machine. The most competitive advantages of this Compact Tofu Machine are small size , with only 20 square meters space and high production efficiency but just need low budget, easy to operate and time-saving in cleaning process, thus it is very popular among the buyers.

Why Compact Tofu Machine We Need?

The Compact Tofu Machine is convenient in production process as it adopts a semi-automatic operating system, which can adjust parameters and set different modules according to product characteristics. It has an intelligent and simple operating process that can be used by one person, to save labor costs, diversify product items, and user-friendly HMI control interface thus to smoothen the operation process. It not only makes the production process faster, but also simplifies the process. The soybeans grinding and separating processes are completed at one time. The constant pressure water tank has automatic water supply which is more effectively and stably control the concentration of soy milk. After grinding and separating processes, the Compact Tofu Machine will cook the soybean milk. As the high concentration soy milk is more difficult to clean than the low-concentration soy milk, this machine is designed to shorten the production pipeline to reduce soy milk residue in the pipeline, thus it can reduce cleaning process and improve production efficiency.

Competitive Advantage of Compact Tofu Machine

In addition, the Compact Tofu Machine can set two-stage cooking method, which uses large volume of steam to quickly cook and then cooks with small volume of steam to make the soy milk mellower, and it also combines the stirring process in its tofu production process. The pumping and adding of coagulant are controlled by software by setting timer, this machine also has quantitative filling and automatic stirring functions. Some relevant parameters such as mixing and stirring can be set according to the different characteristics of each product. The features of this machine such as automatic mixing of the coagulant and circulation the pipeline can avoid the precipitation problem. The tofu mold is automatically moved up and down after the automatic filling into molding device. It also speed up the filling of bean curd to save labor cost and mix the bean curd evenly. The two-stage pressure can be set from tofu pressing to forming process, the pressure can be switched automatically.

Why Choose EVERSOON Compact Tofu Machine ?

The manufacturing process of EVERSOON Tofu Machine complies with CE international certification, including Regular Tofu (Firm Tofu), Silken Tofu (Soft Tofu), Dried Tofu, Soy Milk, Tofu Pudding, and etc. The Compact Tofu Machine has various functions such as grinding and separating machine, soymilk cooking machine, coagulating and curd breaking machine, and a tofu pressing machine. The most competitive advantages of this Compact Tofu Machine are small size, low budget, easy to operate and time-saving in cleaning process, it is very popular among the buyers.

Features

- Multi-Function: able to produce Soymilk, Tofu-Pudding, Firm Tofu, Silken Tofu, Dried Tofu.

- The processes of machine manufactured are according CE international certificate.

- Fast and efficiency production process, the time is shorter for soy milk stayed in the pipe, so the protein losing lower, and then we can get quality and healthy products.

- Touch surface of food are using food grade material SUS304.

- Design with HMI controlling system, and there only need one operator to run this machine.

- Smallest working area request.

- Transparent producing tofu process, fresh and hygiene for the consumer.

- Compact Tofu Machine is suitable for chain store, easy to expand your business with stable profit income.

- Compact Tofu Machine best-selling countries: USA, Germany, France, Italy, Austria, Belgium, Singapore, Indonesia, Vietnam.

SPECIFICATION

| Model No. | FA006051 | FA006052 | FA006053 | FA006054 |

| Built-in Hot Water Generator | V | V | ||

| External Steam Boiler | V | V | ||

| Basic Components | - | - | - | - |

| Ability of Electric Steam Boiler: under 30kgs/cm2 /hr; working pressure: 1kg/cm2 | V | - | V | - |

| Built-in Single Press | V | V | V | V |

| Capacity:dry soybean20~40kgs/hr | V | V | V | V |

| CE Certificate | V | V | V | V |

| F-16 Soybean Grinder | V | V | V | V |

| Soy milk Cooker(100L) (Effective Cooking Volume: 60L) | V | V | V | V |

| Tofu Filling into Molds Device | V | V | V | V |

| Coagulating Tank(20L) | V | V | V | V |

| Stainless Steel Structure | V | V | V | V |

| Single Press Device | V | V | V | V |

| Touched Screen (HMI) and PLC Control System | V | V | V | V |

| Molds:6 PCS (Inner Size 375*375*35mm) | V | V | V | V |

| Remark: Height 35mm or 25mm for option | V | V | V | V |

| Tofu Frame | V | V | V | V |

| Stainless Steel Press Block | V | V | V | V |

| Top Press Plate | V | V | V | V |

| Tofu Cloth | V | V | V | V |

| Vacuum Transportation Device, Feeding Device and Structure | - | - | V | V |

| High Pressure Blower (2HP) | - | - | V | V |

| Vacuum Bucket (8kg) | - | - | V | V |

| Corrugated Sucking Pipe Hose | - | - | V | V |

| Steam Boiler 100kg/cm2/Hr(if choose External Steam Boiler Type)Working Pressure:5kg/cm2/Hr | - | - | - | - |

| Air Compressor(1/2HP) 30L/min; Working Pressure: 5kg/cm2/Hr) | - | - | - | - |

| Stainless Steel Working Table (1200*600*800mm) | V | V | V | V |

| Size | 2,200mm (H) x 1,500mm (W) x 2,200mm (L) | |||

| Weight | Roughly 700kg | |||

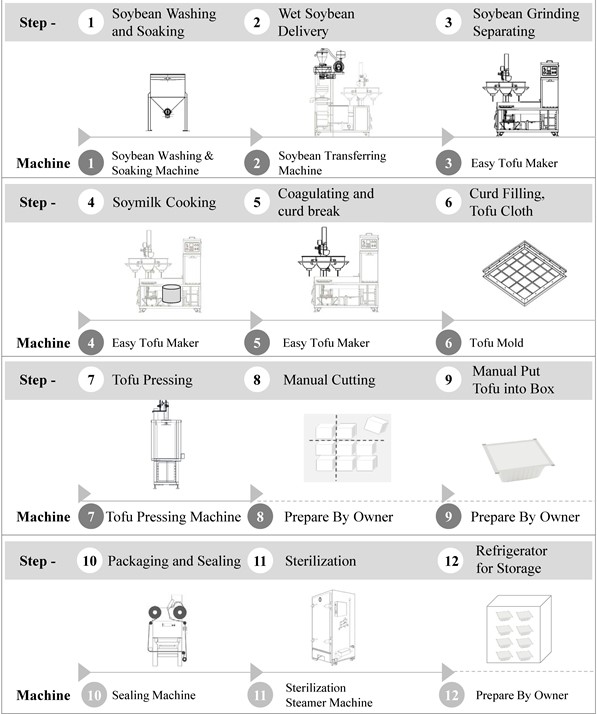

How To Make Tofu With Compact Tofu Machine ?

Step Process

1. Choosing our Soybean Washing & Soaking Machine to reduce labor requirements and upgrade quality of soybean.

2. Choosing our Soybean Transferring Machine to reduce labor requirements and upgrade delivery efficiently.

3. Soybean grinding and separating.

4. Soybean milk cooking, no need to carry the un-cooked Soybean milk for cooking machine, this way also helps you for saving time and labor.

5. Coagulating and curd break, no need to delivery for next process.

6. Filling the break curd into Tofu mold and fixing the Tofu cloth by manual.

7. Pressing by Tofu Pressing Machine, help you reduce molding time and increase productivity.

8. Tofu manual cutting.

9. After finishing the Tofu cutting, manual put the Tofu into Tofu Box.

10. Packaging and sealing with Tofu box to avoid Tofu broken and easily for delivery and sale.

11. To put Tofu into Sterilization (Sterilization Steamer Machine) for sterilization to extend shelf life.

12. Tofu finished products cooling and put into refrigerator for storage.

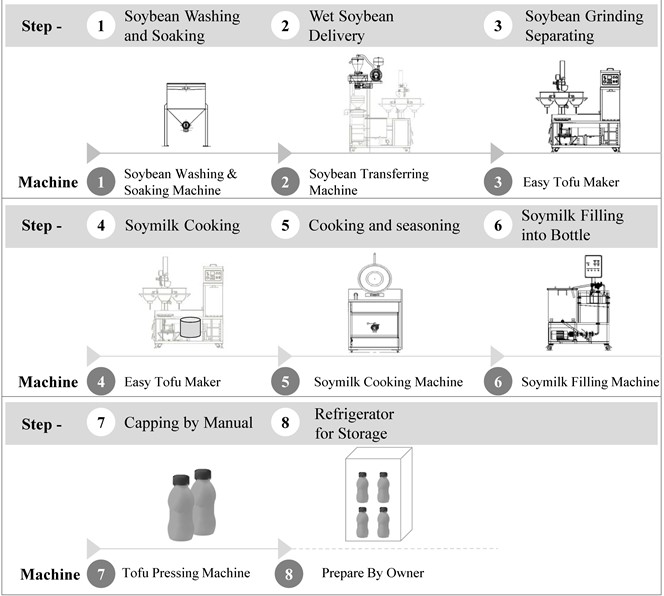

How To Make Soy Milk with Compact Tofu Machine?

Step Process

1. Choosing our Soybean Washing & Soaking Machine to reduce labor requirements and upgrade quality of soybean.

2. Choosing our Soybean Transferring Machine to reduce labor requirements and upgrade delivery efficiently.

3. Soybean grinding and separating in our Compact Tofu Machine.

4. Soy Milk cooking, no need to carry the un-cooked Soy Milk for cooking machine, this way also helping you saving time and labor.

5. Using Soy Milk Cooking Machine (soy milk Cooking Machine- Chef Boiler F-801) to cook and season soy milk.

6. Soy Milk filling into bottle or pouch by using Soy Milk Filling Machine (Semi-Automatic soy milk Filling Machine).

7. Soy Milk bottle capping by manual.

8. Soy Milk product cooling and put into refrigerator for storage.

Applications

What is the different of tofu recipe with Yung Soon Lih (eversoon) Compact Tofu Machine producing?

Different kinds of tofu have different texture, firmness and different meal application on your table, Yung Soon Lih (eversoon) tofu making machine is able to sociable with optional device to produce extra firm tofu, and Asian silken tofu.

Service

Yung Soon Lih (eversoon) Food Machine provides 24-hours online consultation, cooperates with engineers to solve customers’ problems by remote operation, saves people's round-trip time and labor cost, and solves customer problems in a timely and rapid manner.

In addition, food equipment who just started their business or expanded their factories, our senior engineers will go to the company site to survey and help you to plan the layout. In the past 36 years, We had built up a good partnership with our global customers like the Czech Republic, Poland, Canada and also transferred the technical know-how of producing soy milk and tofu to our customers. We were committed to becoming a turnkey solution provider.

- Movies

In this Compact Tofu Machine video clip, you can easily understand how the tofu maker machine makes the Tofu. Including the process of Soybean feeding, grinding, okara separating, raw Soy milk making, Soy milk cooking, pumping to coagulation tank, stirring, and tofu filling.

In this Compact Tofu Machine video clip, you can easily understand how the tofu maker machine makes tofu pudding process.

- Related Products

Soy Bean Milk Boiling Pan Machine

F-801

Delicious food often require elaborate making. soy milk Boiling Pan Machine (Thick Soup Cooking...

Details Add to ListSoybean Rice Grinding & Separating Machine (Soya Grinder Machine)

F-16

1. The major difference in various types of the Soybean Rice Grinding & Separating Machine...

Details Add to ListSingle Presser of Tofu Pressing Machine

Our Tofu Pressing Machine are available to run with one operator only, you can easily estimate...

Details Add to List- Files Download

Soybean Soaking & Washing Machine

Our Soybean Soaking & Washing Machine are using compressed air injected into the water to roll...

Details Add to ListSoybean Transferring Machine

After the Soybean finished soaking process, we use vacuuming transferring system to deliver...

Details Add to ListTofu Pressing Machine

Tofu Pressing Machine is made of stainless steel material, hygienic, beautiful and durable....

Details Add to ListTofu Box Sealing Machine

Air pressure type automatic sealing machine – it is suitable for sealing of various materials...

Details Add to ListSterilization Steamer Machine

The operation time and temperature of the Sterilization Steamer Machine can be preset. The steamer...

Details Add to ListSoy Milk Filling Machine

Soy Milk Filling Machine (Semi-Automatic soy milk Filling Machine) is able to fill PP bottle...

Details Add to ListSoy Milk Bag Vacuum Package Machine

Using Soy Milk Bag Vacuum Package Machine for soft pouch packaging. After soy milk Bag Vacuum...

Details Add to ListCompact Tofu Machine - Small Tofu Machine For Business | Professional Soybean Processing Equipment Supplier For 32 Years in Taiwan | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a Compact Tofu Machine manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

EVERSOON, a brand of Yung Soon Lih Food Machine Co., Ltd., is a leader of Soy Milk and Tofu Machines. Being a guardian of food safety, we share our core technology and professional experience of Tofu production to our worldwide customers. Let us be your important and powerful partner to witness your business growth and success.