Şirket Profili

Profesyonel soya gıda makinelerinde lider

eversoon, Yung Soon Lih Food Machine Co., Ltd. markası, müşterilere iyi çözümler sunmak için uzmanlık ve beceri kullanarak makine üretimi yapmaktadır. Makine imalatı alanında, P&ID planlamasından özel makinelerin tasarlanması ve üretimine kadar 36 yıllık deneyime ve AR-GE ekiplerine sahibiz. Her adımda sizin için en profesyonel ekip planlama yapmaktadır.

Kurucumuz, Brian Cheng, vegan yaşam tarzını dünyaya tanıtmaya kararlıdır. Şirketin vegan yiyecek günlerini her ayın ikinci ve dördüncü Çarşamba günleri olarak belirlemekte ve tüm çalışanları ve tedarikçileri, Küresel ESG girişimleri için harekete geçmeye davet etmektedir.

Yung Soon Lih, bir ESG sürdürülebilir işletme haline gelmiştir. Ayrıca, makinenin her parçasının doğru olduğundan emin oluyoruz. Tam bir makine hizmet sağlayıcısı olmak, müşterilerin ihtiyaçlarını karşılamak için maliyet tasarrufu sağlayan ve yenilikçi üretim çözümleri üretmek için deneyim ve teknolojiye sahip olmayı gerektirir.

Hayvanların yaşamına saygının artması ve hayvansal protein yerine bitkisel protein tercih eden tüketicilerin bilinçlenmesi ile birlikte, dünya genelinde tofu, soya sütü, yonca filizi ve vegan yiyecek makinelerine olan talep gün geçtikçe artmaktadır. Piyasanın ihtiyaçlarını karşılamak için, üretim hatları ve mekanik ekipmanlar için özelleştirilmiş tasarım hizmetleri sunuyoruz ve tüketicilerin ihtiyaçlarını karşılayan soya gıdalarının üretimine yardımcı oluyoruz. Bugün, Yung Soon Lih tofu ve soya sütü üretim hatları, Avrupa ve Amerika'daki müşteriler tarafından yaygın olarak kullanılmaktadır. Bu hatlar, bitkisel bazlı protein tüketimi ihtiyacını büyük ölçüde karşılayabilir ve karbondioksit emisyonlarının azaltılmasıyla ilgili çevre koruma konusunda önemli bir katkı sağlayabilir.

Brian, tofu ve soya sütü makineleri işini vegan ve gıda çevre koruma hareketiyle birleştirmiş ve bu şirketin ESG sürdürülebilir yönetiminin başlangıcı haline gelmiştir. Şimdi şirket çeşitli görevlerde ESG yönetişimini uygulamaya devam edecektir.

▲ Yung Soon Lih'in güçlü bir ekibi.

Gıda Endüstrisi Araştırma ve Geliştirme Enstitüsü ve Tasarım Çözüm Ekibi

Yung Soon Lih, gıda işleme endüstrisinde 36 yıldır faaliyet göstermektedir ve müşterilere çeşitli çözümler sunmaktadır. Sizin yerlerinizi ziyaret ediyor, sektörünüzü öğreniyor ve hedeflerinizi, zorluklarınızı, ihtiyaçlarınızı, sınırlamalarınızı ve gereksinimlerinizi anlıyoruz. Sizinle el ele çalışıyor ve sizin için neyin gerekli olduğunu anlıyoruz. Ayrıca, uzun süre gıda üretim endüstrilerinde araştırma yapmış uzmanlarımız bulunmaktadır.

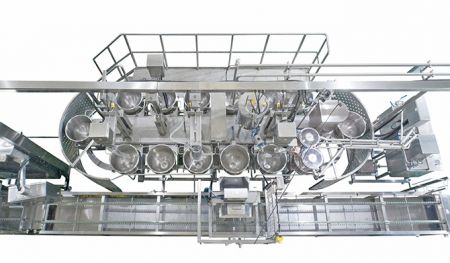

▲ Makine üretim sürecinin tüm detaylarını kontrol eder ve onaylarız.

Etkinliği Maksimize Edin

Yung Soon Lih'ın amacı sadece gıda makinesi geliştirmek ve tasarlamak değil, aynı zamanda tofu, soya sütü üretim prosedürü üzerine yapılan araştırmalara odaklanarak üretim verimliliği ile yiyecek lezzeti arasında denge bulmaktır, özellikle tofu ve soya sütü üretim alanında. Yung Soon Lih'ın soya fasulyesi yemek Gastrosoph olduğunu söylemekten eminiz! Turnkey üretim hattınızı genişletmeyi planladığınızda büyümenize eşlik eden benzersiz bir ortak olabiliriz.

Sadece üretim makineleri geliştirmiyoruz, aynı zamanda pazar bilgisi toplayan, ürün fiyatlarını analiz eden, mekanik maliyetleri hesaplayan, veri yoluyla çıktı üreten ve müşterilere maliyet ve kayıplarını azaltmalarına yardımcı olan bir ekip de bulunuyoruz. Yung Soon Lih, soya işleme makinelerinin protein çıkarma oranını artırabilir ve üretim sürecinin verimliliğini maksimize edebilir. Bu ruh bizi rekabetten öne çıkarıyor. Deneyimli ekibimizin her müşteriyle çalışırken sunduğu budur. Bu uzmanlık, bizi rakiplerimizden ayıran şeydir.

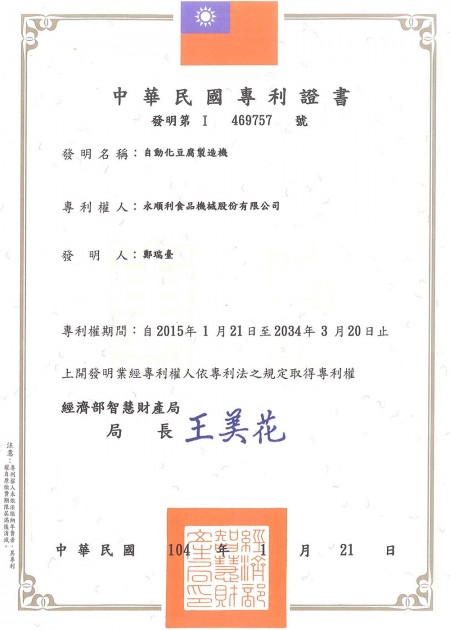

Yung Soon Lih Food Machine, Tayvan'da en çok soya fasulye makinesi patentine sahip oldu.

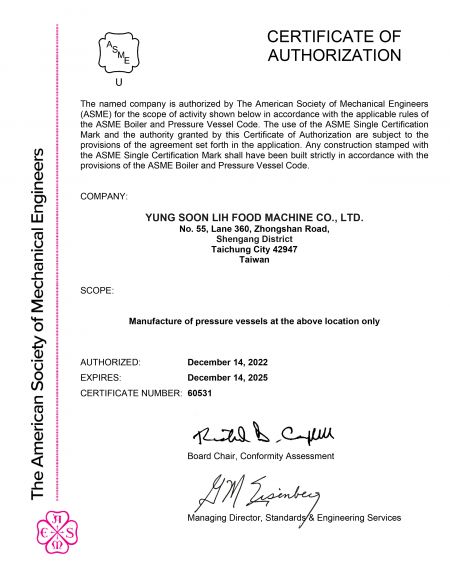

Soya fasulyesi işleme teknik gelişimine sadece derinden dahil olmakla kalmadık, aynı zamanda bilgisayar kontrol ve izleme sistemini ekipmanlarımıza dahil ettik. Tofu, soya sütü, fasulye filizi, yonca anahtar teslim üretim hattını geliştiriyor ve tasarlıyoruz ve size yüksek kaliteli ve verimli çözüm sağlayarak otomasyon yönetimi hedeflerinize ulaşmanıza yardımcı oluyoruz. Ayrıca, müşterilere özel makine ve iyi bir çözüm sunabilen bir Ar-Ge ekibimiz bulunmaktadır. Bu arada, uluslararası sertifikaları ve patentleri olumlu bir şekilde uyguluyoruz. Güvenle soya fasulyesi gıda makinesi üreticisinin lideri oluyoruz.

▲ CE sertifikalarımız, UL sertifikalarımız, patentlerimiz vb. bulunmaktadır.

Piyasa talebini karşılamak için hizmet sağlamak, bize Mavi Okyanus pazarını bulmada yardımcı olacaktır.

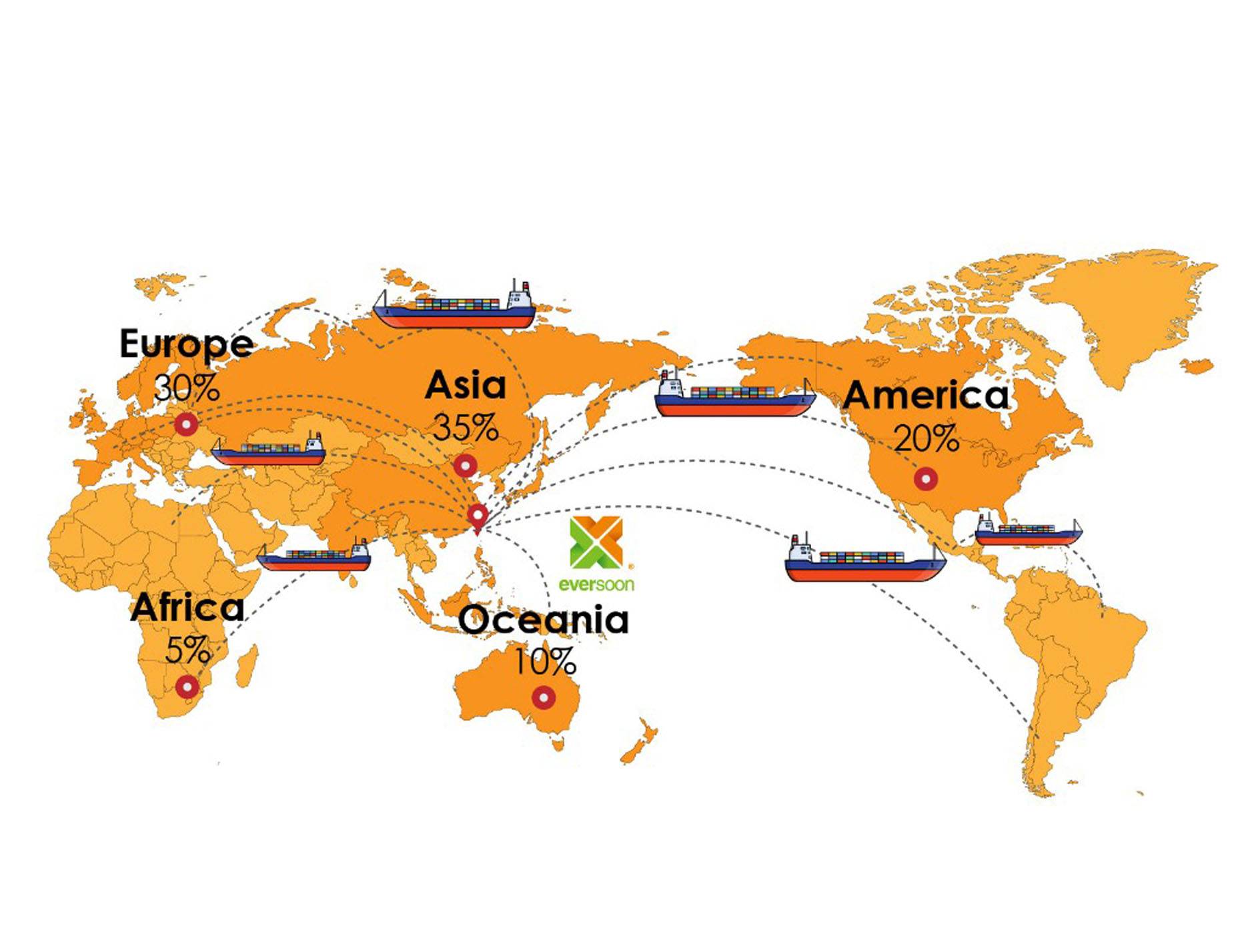

Vejetaryenlerin nüfusu sürekli olarak artıyor çünkü sebze proteininin önemi ve avantajları tıp çevreleri tarafından kanıtlanmıştır, bu yüzden Avrupa ve Amerika ülkelerinden tofu, soya sütü, fasulye filizi, yonca makinesi gibi talep miktarı giderek artıyor. Piyasanın artan talebi, müşterinin tüketici talebine uygun soya ürünleri üretmesine yardımcı olmak için anahtar teslim üretim hattını ve makineleri özelleştirmemizi zorladı. Tofu ve soya sütü ekipmanlarımız ve üretim hattımız Amerikan ve Avrupa müşterileri tarafından iyi ve geniş bir şekilde benimsendi.

Gururumuz, 2010 yılından bu yana Avrupa, Asya, Amerika, Okyanusya ve daha fazla ülkede bulunan gıda ve içecek üreticileri için anahtar teslim üretim hatları hizmeti sunmuş ve tasarlamış olmamızdır. Özellikle bazı belirli gıda üreticilerinden, onların Tofu, soya sütü üretim deneyimleri olmadığı için, sadece Yung Soon Lih'e anahtar teslim üretim hattı tasarlamalarını değil, aynı zamanda soya fasulyesi işleme, bilgi birikimi ve soya ürünlerini nasıl yapacaklarını öğretmelerini umarak, temel teknikleri de sağlamamızı bekliyorlar. Ayrıca, makinenin parametrelerini yerel lezzet ve tat için ayarlamak için özeliz, böylece tofu ve soya sütünün yerel tada uyduğundan ve hızla pazara erişildiğinden emin oluruz.

▲ Yung Soon Lih Food Machine, dünya genelinde gıda ve içecek üreticileri için anahtar teslim üretim hatları sunmuş ve tasarlamıştır.

24 saat hizmet sunuyoruz.

Yung Soon Lih, 24 saat çevrimiçi danışmanlık sağlar, mühendislerle işbirliği yaparak müşterilerin sorunlarını uzaktan işletme ile çözer, insanların gidiş-dönüş zamanını ve işçilik maliyetini tasarruf eder ve müşteri sorunlarını zamanında ve hızlı bir şekilde çözer.

Ayrıca, işine yeni başlayan veya fabrikasını genişleten gıda üreticileri için, kıdemli mühendislerimiz şirketin sahasına giderek inceleme yapacak ve düzenleme planlamasında size yardımcı olacak. Geçen 36 yılda, Yung Soon Lih Çek Cumhuriyeti, Polonya, Kanada gibi küresel müşterilerimizle iyi bir ortaklık kurmuş ve ayrıca ürettiğimiz soya sütü ve tofu'nun teknik bilgisini müşterilerimize aktarmıştır. Anahtar teslim çözüm sağlayıcı olmaya kararlıydık.

Daha fazla bilgi için lütfen bize ulaşın.

| Zaman | Başarı |

|---|---|

| 2020 |

Mesleki eğitim planı için işbaşı eğitimi edinildi. Fenomen tabanlı plan - Covid-19'un etkisinden geleneksel endüstrilerin CITD İnovatif araştırma ve geliştirme çalışmaları Endüstriler için AI Sertifikası ve Ürünlerin Ticarileştirilmesi |

| 2019 | Bireysel Tek Makineler için UL & NSF Sertifikası Alındı. |

| 2019 | TTQS, Yetenek Kalite Yönetim Sistemi Sertifikası Alındı. |

| 2018 | Ekonomi Bakanlığı Uluslararası Ticaret Bürosu'ndan Uluslararası Pazar Genişleme Planı Hibesi Alındı. |

| 2016 | Ekonomi Bakanlığı'ndan Teknoloji Araştırma ve Geliştirme Projesi Alındı - geleneksel endüstri için teknoloji geliştirme desteği. |

| 2015 | Dünyaca ünlü şirketlerle işbirliği yaparak dünya çapında bayi, acente ve distribütörler alındı. |

| 2009 | Kompakt Tofu İşlemcisi ve (Küçük ve Kolay Tofu yapıcı / Tofu makinesi) geliştirin ve Tayvan hastasına ödül verildi. |

| 2007 | Tofu ekipmanında CE belgesi alındı ve tofu üretim hattındaki çoğu ekipman. |

| 2005 | Çeşitli gıda işleme makinelerini entegre edin ve araştırma ve geliştirmeyi yükseltin. |

| 2003 | ISO 9001 sertifikası verildi. |

| 1995 | Sürekli büyüme ve işi uluslararası pazara taşıma, Amerika ve Avrupa ülkelerine Tofu ve soya sütü ekipmanı ve ürün hattını tanıtma. |

| 1994 | İş genişlemesi için yeni bir fabrikaya taşındık, Tofu ve soya sütü ekipmanlarını ve anahtar teslim üretim hattını büyüttük. |

| 1993 | İlk fasulye öğütme ve soya sütü pişirme makinesi duyuruldu. |

| 1989 | Fasulye işleme makine endüstrisine yatırım yapmaya kararlıydık. |

Şirket Vizyonu

Yönetim

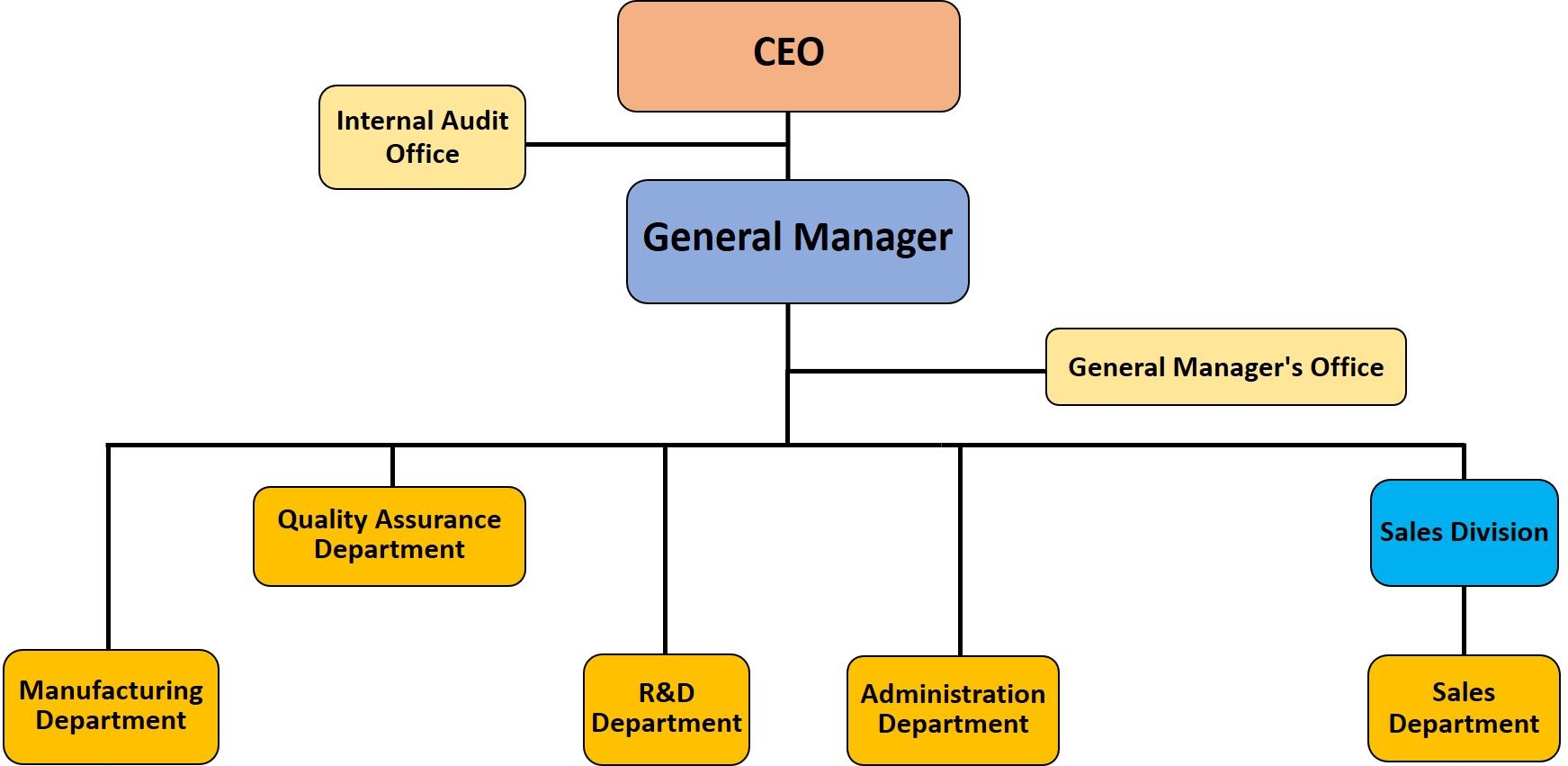

Şirket Yapısı

- Filmler

- Ürün Patentları

- TTQS sertifikası

- Üyelik sertifikası

- ASME U sertifikasyonu

- İlgili Ürün

-

Entegre Soya Sütü Makinesi

Öğütme/Ayırma Makinesi ve Pişirme Makinesi, soya sütünü düzgün bir akışta üretir. İlk olarak, Soya fasulyesi Öğütme/Ayırma Makinesine...

Detaylar Sepete ekleTwin Grinding & Okara Ayırma & Pişirme Makinesi, VEJETARYEN ET “TOFU” ÜRETMEK İÇİN İYİ BİR MAKİNADIR

Kapasitesi 200-220 kg/saat'a kadar olan Twin-Grinding & Okara Ayırma & Pişirme Makinesi sunuyoruz.

Detaylar Sepete ekleTOFU PEYNİRİ DOLDURMA VE KALIBI PIRINÇ KONVEY MAKİNESİ

Otomatik tofu pıhtılaşma makinesi, soya sütü yalıtım aşaması > nokta hamuru > pıhtılaşma > peynir kırma > su emme gibi işlemleri gerçekleştirebilir,...

Detaylar Sepete ekle - Dosyaları İndir

-