-

English

- English

- Español

- Português

- Français

- Italiano

- Deutsch

- Русский

- Suomen

- Svenska

- Dansk

- česky

- Polska

- Nederlands

- Türkçe

- العربية

- हिन्दी

- Indonesia

- ไทย

- Bahasa Melayu

- Việt

- Български

- Javanese

- slovenčina

- slovenščina

- తెలుగు

- Filipino

- Română

- فارسی

- বাঙ্গালী

- українська

- Magyar

- עברית

- Norsk

- Eesti

- Hrvatska

- Gaeilge

- 中文 (繁體)

- 中文 (简体)

- 日本語

- 한국어

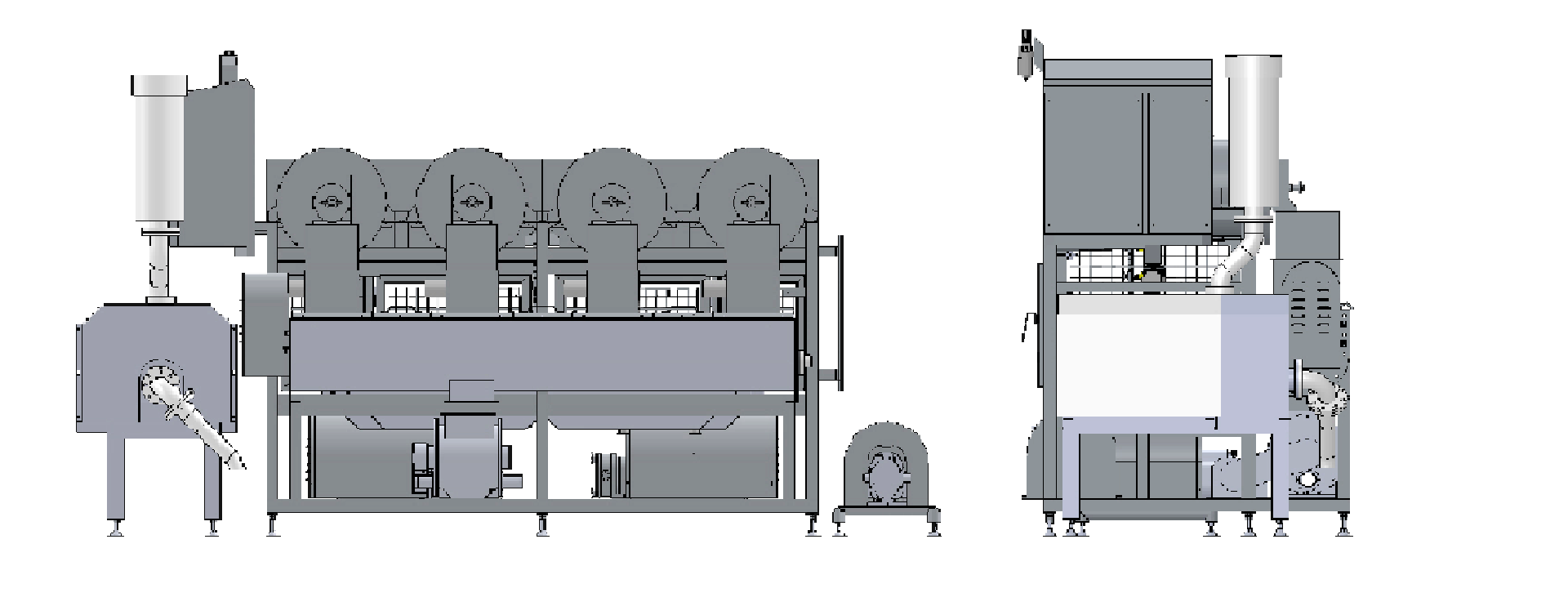

Soybean Okara separation Extrude-Spiral extrusion

Okara separation Extrude-Spiral extrusion

Screw extrusion dehydrator is a kind of equipment used for coagulation and dehydration. It is mainly composed of screw, cylindrical cover and cone. The screw shaft and the output shaft of the reducer are connected by a flexible coupling. Screw extrusion dehydration is used for dehydration of high humidity okara materials.

Features:

Apply with HMI control for machine operation, adjustment and parameter are all set up with monitor for high efficient and easy setting.

High efficient automatic isolation for buffering, squeezing and micro-filtering are all running in one machine with one time running.

Capable to set up with different types of soymilk product with different parameters.

The machine is made of Galvanized Iron with beautiful, hygienc and durable design.

Automatical production with easy operation, assembling & disassembling, and setting for CIP are all quick and clear.

It is suitable wide range of Brix 6-13 (Soymilk concentration) Okara seperation with good seperation performance.

The squeezing machine is designed quick release unit to quick release the cover, quick release inner filter and outer filter. After production, it can be matched with CIP circuit and COP cleaning the squeezing machine to reduce cleaning time and reduce cleaning costs.

Design in screw type Okara seperation principle, and the dryness of the separated Okara is good to increase the soymilk extraction rate.

Features

- Soybean juice is squeezed out from cooked soy milk -> separation -> okara is transported out -> heat preservation and transportation of soy milk

Specification

- Customized design by customers' capacity request.

|

|

|

|

|

R121055-26 |

|

|

3278mmX1564mmX2200mm |

|

Voltage and Phase |

AC400Vx3Øx50Hz |

|

Power consumption |

14.77KW |

|

Air need |

60 L/min |

Applications

TYPICAL PRODUCT Applicable products: Suitable for the grinding and separation operation of soybeans and other types of beans. It can be used to produce regular tofu (firm tofu), silken tofu (soft tofu), fried tofu, vegetable tofu, tofu burger, tofu sausage, long-lasting soy milk, fresh soy milk, dried tofu, and tofu pudding.

Services

Yung Soon Lih Food Machine provides 24-hour online consultation, cooperates with engineers to solve customers’ problems by the remote operation, saves people's round-trip time and labor cost, and solves customer problems in a timely and rapid manner.

In addition, food manufacturers who just started their business or expanded their factories, our senior engineers will go to the company site to survey and help you to planning the layout. In the past 36 years, We had built up a good partnership with our global customers like Czech Republic, Poland, Canada and also transfer the technical know-how of produced soy milk and tofu to our customers. We were committed to becoming turnkey solution provider.

- Movies

Tags

- Grinding And Separating Machine

- grinding of soybean

- soy bean grinder

- soy grinder

- soya bean grinder

- soya bean grinder and separator

- soya grinder

- soya grinder machine

- soya grinder with separator

- soybean machine

- soybean milk grinding machine

- soybean stone grinder

- tofu grinder

- tofu grinder machine

- soymilk Extruding Filter

- food equipment

Soybean Okara separation Extrude-Spiral extrusion - Okara separation Extrude-Spiral extrusion | Taiwan-Based Soybean Processing Equipment Manufacturer Since 1989 | Yung Soon Lih Food Machine Co., Ltd.

Based in Taiwan since 1989, Yung Soon Lih Food Machine Co., Ltd. has been a Soybean Okara separation Extrude-Spiral extrusion manufacturer that is specilized in soy bean, soy milk and tofu making sectors. Unique design soy milk and tofu production lines built with ISO and CE certifications, sold in 40 countries with solid reputation.

We are the first food machine manufacturer whom developed the European Tofu turn-key production line, which can produce Asian Tofu, and Soy Milk processing equipment. Our tofu production machines are specially design and able to produce Tofu Burger, Vegetable Tofu, Smoked Tofu, Tofu Sausage to satisfy consumers' demand from the American and European market.